Spc Resilient Flooring Eir on-Line Embossing Extrusion Production Line

Forsun Ultra-hard Material Industry Co., Ltd.Base Info

Description

Basic Info.

Model NO. SJSZ110/220 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Voltage 220-415V / 50-60Hz 3 Phase Power 485-750kw Per Line Production Line Layout 50m (L) * 5m (W) * 8m (H) Calender Five Roller Deliver Time 45 Days Plank Thickness 2-9mm T-Die 1050/1350 Online Embossing Better Than 95% Transport Package PE Wrapping Film, Fumigating Wooden Cases. Specification CE, SGS, UL, TUV, CSA, ISO Trademark BOYU Origin Wuxi, Jiangsu, China HS Code 8477209000 Production Capacity 200 Sets Per YearProduct Description

Spc Resilient Flooring EIR on-Line Embossing Extrusion Production LineSJSZ110/220 Conical Twin-Screw SPC Flooring Production Line

I. Design parameters

| No. | Items | Description |

| 01 | Operation conditions | 380V/3 phases/60Hz. (or customizable as per different country's standard voltage ) |

| 02 | Materials used | PVC powder, calcium carbonate, stabilizer, lubricant, small materials. Main Material and proportion: PVC: CaCo3 = 1:1 :2~3 |

| 03 | Extrusion rate | Daily capacity: 25-32 Tons/ 24 hours about 3000m2/ day for 4mm finished SPC flooring |

| 04 | Product specifications | Maximum width is 1050mm, thickness =2-9mm. Normal finished board width: 980mm Normal finished board thickness: δ=1.5~4.0mm |

| 05 | Total power of whole machine line | About 700KW (The exact total power may something floating as per different configuration requirements |

II.Equipment List & Quantity

| No. | Equipment Name | Quantity | Remark |

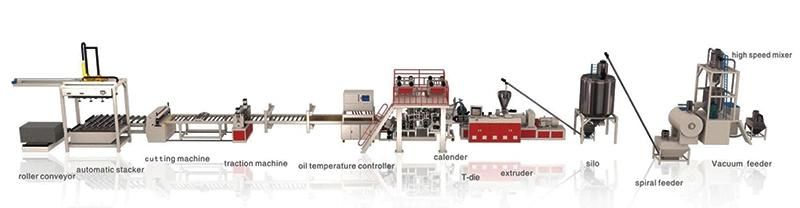

| 01 | Φ110/220 Conical twin-screw extruder | 1 Set | |

| 02 | Extrusion die | 1 Set | |

| 03 | Five-roller calender | 1 Set | |

| 04 | Film unwinding mechanism & magnetic powder controller | 2 Units | For two working position |

| 05 | Oil roller heating system (integral) | 1 Set | 4 units |

| 06 | Cooling bracket | 1 unit | |

| 07 | Longitudinal edge cutting mechanism | 1 unit | |

| 08 | Traction machine | 2 sets | |

| 09 | Length meter | 1 Set | |

| 10 | Plate shearing machine | 1 set | |

| 11 | Automatic plate lifting and stacking system | 1 unit | |

| 12 | Electric control cabinet | 1 unit | |

| 13 | Cooing water spray tank | 1 unit | |

| 14 | wear layer pre-heat device | 1 unit |

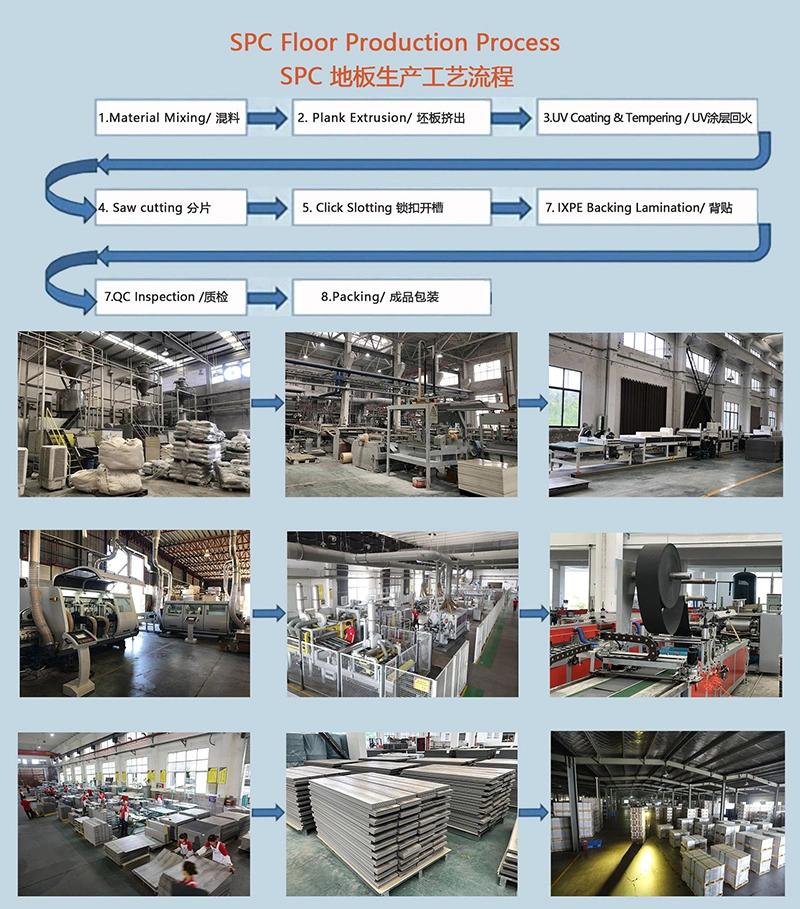

III.Production Flow

Material mixing → Extruder → Calender→ Cut-to-length →Stacking →UV coating →Saw cutting →

Slick slotting →Backing limitation →QC inspection → Packing

IV. Machine Line Layout

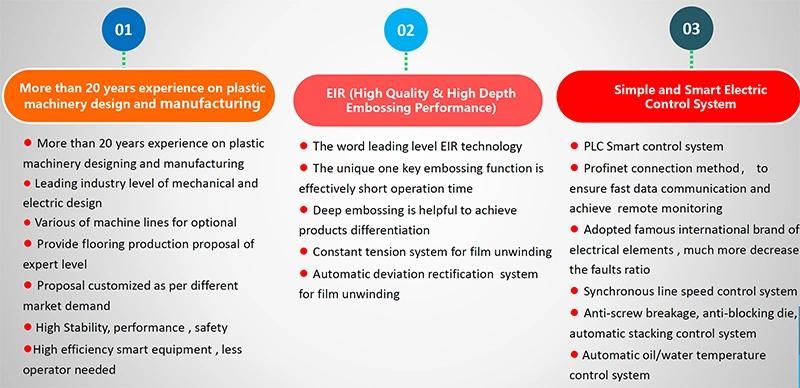

V. Advantages of BOYU WPC Production Machine Line

VI.Services

VII. Project Case

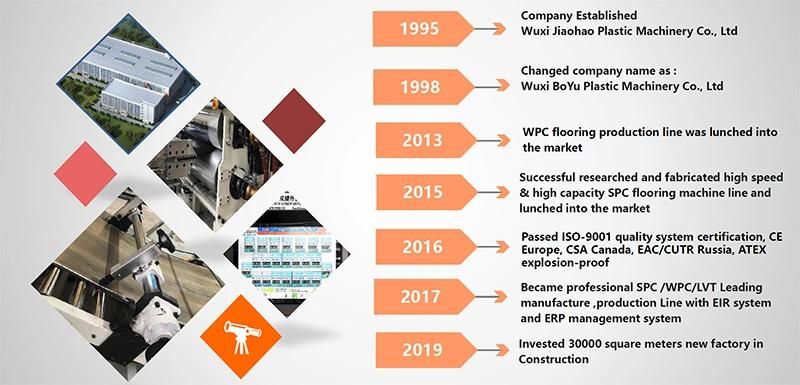

VII. Boyu Company Profile

VIII. Patents Certificates

BoYu On-line EIR Technology - United States Patent

BoYu On-line EIR Technology - Europe & Taiwan Patents