10 Tons/Hour Paddy/Rice Milling Plant

Nanjing Zhanyi Technology Co., Ltd.- Warranty:12 Months

- Type:Rice Mill

- Application:Rice flour, Paddy,Rice

- Voltage:380V

- Appearance:Vertical

- Press Materials:Paddy

Base Info

- Model NO.:Flour Milling Machine

- Press Series:Fourth

- Condition:New

- Customized:Customized

- Capacity:Input 10 Tons Per Hour

- Factory Visiting:Yes

- Color:According to Customers′ Need

- Raw Grain:All Kinds of Paddy

- Final Product:Fine Rice

- Supply Type:Manufacturer

- Yield Rate:60-65%

- Quality:High Standard

- Advantage:High Efficiency

- Transport Package:Bubble Film and Wooden Case

- Specification:CE, ISO

- Trademark:HNLY

- Origin:Jiaozuo of Henan Province, China

- HS Code:8437800000

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. Flour Milling Machine Press Series Fourth Condition New Customized Customized Capacity Input 10 Tons Per Hour Factory Visiting Yes Color According to Customers′ Need Raw Grain All Kinds of Paddy Final Product Fine Rice Supply Type Manufacturer Yield Rate 60-65% Quality High Standard Advantage High Efficiency Transport Package Bubble Film and Wooden Case Specification CE, ISO Trademark HNLY Origin Jiaozuo of Henan Province, China HS Code 8437800000 Production Capacity 100 Sets/YearProduct Description

10 Tons/Hour Paddy/Rice Milling Plant Rice milling plant brief introduction:(1)Rice finishes being cleaned by vibrating sieve, destoner and magnetic separator, and then through grinding roller for hulling.

(2)After air blowing, entering milling machine, the paddy finishes the process of husking and milling in succession.

(3)Then husk, chaff, and white rice flour are pushed out of machine respectively.

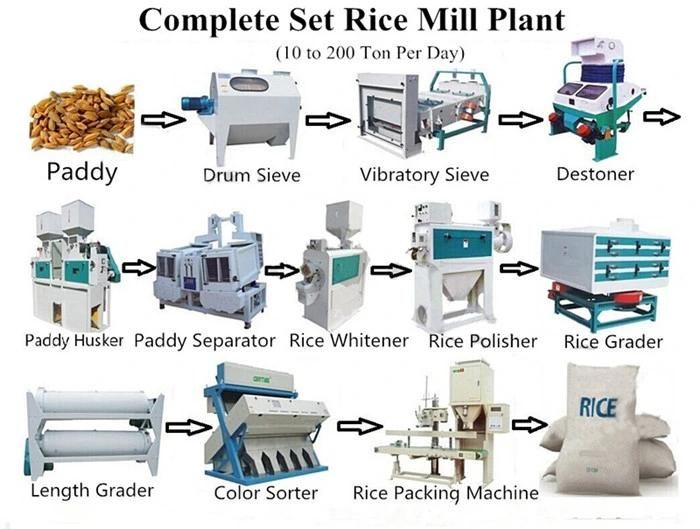

Flow Chart:

Paddy Cleaner → Destoner → Paddy husker → Paddy Separator → Rice Whitener → water polisher → Rice Grader → Color Sorter → Packing

The working site of 10 ton/hour Paddy Rice Milling Plant/Rice mill machine

Rice milling process:

| Pre Cleaning | Clean out all impurities and unqualified grains from raw paddy |

| De-stoning | Separate stones, clods from rice |

| Parboiling (Alternative) | Improve the nutritious quality and milling recovery percent during husking, polishing, whitening |

| Husking | Remove husk from rice |

| Husk Separation | Separate husk from brown rice/ unhulled rice |

| Rich Separation | Separate the unhusked paddy from brown rice |

| Whitening | Remove all or part of the bran layer and germ from brown rice |

| Polishing | Improve appearance of milled rice by removing bran and by polishing kernel |

| Color Sorting (Alternative) | Remove foreign matter such as mould, broken rice from milled rice |

| Packing | Pack the pure rice |

Packaging

Packaging:Big parts are packed by plastic bubble film and small parts by wooden case.

Shipping

Shipping: All the machines will be sent by sea, if you need other kind of transportation, please inform us in advance.And all the machines would be shipped timely after the receipt of payment. Before and after shipping, we will take photos of the machines and send them to our clients.

Our Services

1. One year quality warranty for the machine

2. Engineers service for overseas installation

3. Whole-life after-sales service and free consultation

4. Customized requirements available

5. Technicians guide at the site.

6.24Hr online service

Company Information

1. About us

Henan Institute of Grain Machinery Manufacturing Co., Ltd. is established by the academy of Henan University of Technology. As a large joint-stock enterprise integrating technology, manufacture and sales, our company is specialized in the production of grain and oil machinery, agricultural and sideline machinery. Cooperating with Henan Mechanical Design and Research Institute and Henna University of Technology (Former Zhengzhou Grain College), Henan Institute of Grain Machinery Manufacturing Co., Ltd. has carried out the research and application of grain machinery, oil machinery, construction machinery,food machinery and feed machinery, etc.

We provide a turnkey project of our machinery, including special design, installation, commissioning and training workers.

Any questions, please don't hesitate to contact us!