Rice Bran Oil Extraction Equipment Solvent Extraction Plant

Jiangmen Jianghai Lianhe Colour Packing and Printing Co., Ltd.- After-sales Service:Engineer Available to Service Machine Overseas

- Warranty:1 Year

- Type:Pressing Machines

- Application:All

- Voltage:380V

- Appearance:Vertical

Base Info

- Model NO.:HUATAI oil

- Press Materials:Soybean

- Press Series:Second

- Condition:New

- Customized:Customized

- Certificates:CE, ISO

- Transport Package:Standard Packing for Export

- Specification:20TPD to 1000TPD

- Trademark:Huatai Machinery

- Origin:China

- HS Code:847920000

- Production Capacity:200 Sets,Year

Description

Basic Info.

Model NO. HUATAI oil Press Materials Soybean Press Series Second Condition New Customized Customized Certificates CE, ISO Transport Package Standard Packing for Export Specification 20TPD to 1000TPD Trademark Huatai Machinery Origin China HS Code 847920000 Production Capacity 200 Sets/YearProduct Description

Rice Bran Oil Extraction Line Rice Brain Oil Mill Rice Bran Oil Solvent Extraction PlantProduct Description:

What can we do?

1.Provide all kinds of oil machine: mini oil plant, oil extraction mill, oil refinery machine, small oil factionry mills, large oil processing line, etc.2.Single oil machine and turnkey oil processing project are both available.

3.Oil plants include: coconut oil machine, palm oil mill, sesame oil plant, soya bean oil machine,rice bran oil extraction machine , peanut groundnut oil plant, rapeseed oil machine, corn germ oil machine and other vegetable oil plant.

4.Custom design for household oil machine and oil factory turnkey project with installing and adjusting.

Solvent extraction plant Advantages

- High oil yield , obvious economic benefit .

(2) Residual oil rate in the dry meal .

(3) Improving the quality of the meal .

(4) Low processing cost , high labor productivity.

| Residual oil in meal | ≤1% |

| Solvent consumption | ≤3Kg/T(6#solvent oil) |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Steam consumption | ≤280Kg/T (0.8MPa) |

| Finished meal moisture | ≤ 10-13% (adjustable) |

| Residual solvent in finished meal | ≤ 300PPM (qualified detonated experiment) |

Sections of process:

A. oil making machine pre-treatment workshop introduction:

1. Raw materials cleaning2. Raw materials softening

3. Raw materials flaking

B.solvent extraction plant price Main products:

1.Solvent pumps2.Roary extractor

3.DTDC

4.Miscella tank 1st

5. Miscella tank 2nd

6. Miscella stripping

7. condensers

C. oil making machine refining workshop introduction:

1. oil degumming and deacidification2. oil decolorizing

3. oil deodorization

Details of sections:

A,oil making machine pretreatment workshop introduction:

B.Solvent extraction plant price Mian products:

1.Solvent pumps: continuously spray solvent to the rotary-type extractor2.Roary extractor: Spray and soak the pre-pressed cake with solvent pressed cake with solvent so that oil fats can be dissolved in solvent (form miscella).After processing,you can get wet meal and miscella (mixed oil).

3.DTDC: used to separate the solvent from the wet meal.

4.Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1ist , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

5.Miscella tank 2nd: the purified miscella will be pumped into it.

6.Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

7.condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Workshop details:

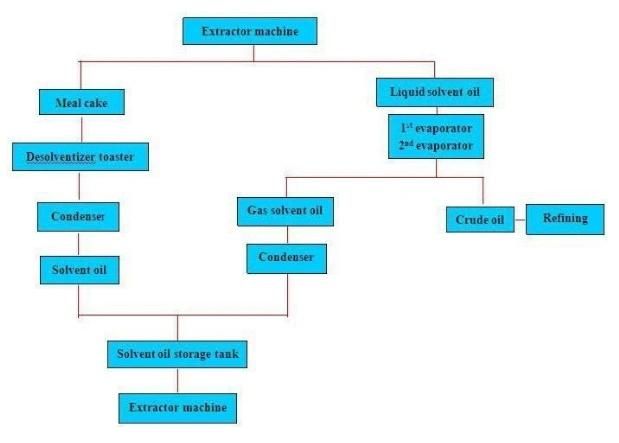

leaching (extraction), evapo-separate (embryos solvent material separation), evaporation (oil and solvent separation), condensation,

exhaust gas recycling, water recovery and other systems

Working principle:

Leaching system is an oil extraction through soaking or spraying prepressed cake by a certain organic solvent. The principle of this

part is the different solubility of solvent.

Main process:

(1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is sent to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is

separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can

get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

Packing and Delivery: