-

WPC Hollow Board Extrusion Line

Technical forWPC Hollow Board Extrusion LineModelGYF600GYF800GYF1000GYF1250Max.width of product(mm)60080010001250Extruder modelGSZ65/132GSZ80/156GSZ92/188GSZ92/188Max.extrusion capacity(kg/h) 250 350 450 550Extruder power(kw) 37 55 1

-

Plastic Hollow Board/Panel Production and Extrusion Line

Technical forPlastic Hollow Board/Panel Production and Extrusion LineModelGYF600GYF800GYF1000GYF1250Max.width of product(mm)60080010001250Extruder modelGSZ65/132GSZ80/156GSZ92/188GSZ92/188Max.extrusion capacity(kg/h) 250 350 450 550Extruder

-

PVC WPC Foamed Plate Extrusion Line

PVC WPC FOAMED PLATE MAKING MACHINEModelGYF1220-AGYF1220-BGYF1500-CExtruerGSZ80/156GSZ80/173GSZ92/188Max.output(kg/h)350600650Die width(mm)132013201550Production width(mm)122012201400Power(kw)146170205GSZ80/156 ExtruderSupplier of el

-

PVC Trunking Wire Casing Production Line

SPECIFICATIONS FOR PLASTIC-STEEL PROFILE EXTRUSION LINEModelScrew Diameter(mm)Main Moter(kw)Output Capacity(kg/h)GSZ-4545/10015/18.560/80GSZ-5151/10518.5/2280/110GSZ-5555/11022/30120/150GSZ-6565/13237/45280&s

-

PVC Two Cavity Production Line

Basic Info. Model NO. GYF C

-

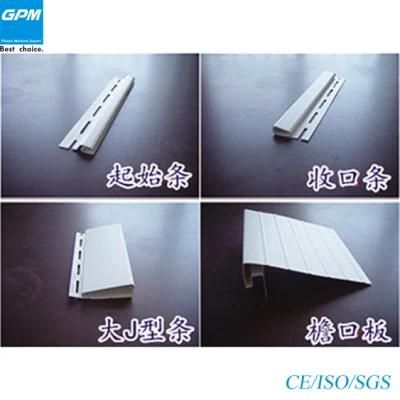

PVC Siding Panel Extrusion Line

SPECIFICATIONS For PVC Siding Panel Extrusion LineLine modelLow speed lineHigh speed lineModelGYF400-SGSGYF400-SGSTotal power42.3kw52.8kwMax.speed8m/min20m/minWater cooling5m³/h8m³/hCompressed air0.6Mpa0.6MpaFor choosing the proper machine

-

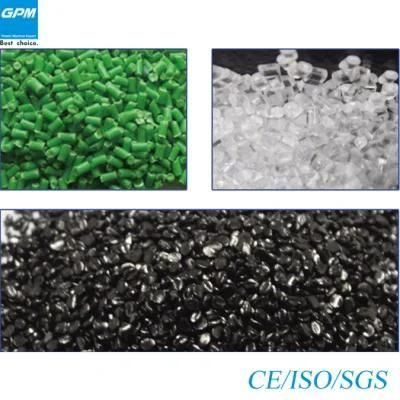

Cost-Effective Plastic Granulator Unit

Conical twin-screw pelletizing extrusion unitsModelOutput capacity(kg/h)Applicable raw materialsGSZ6565/132300 PVCGSZ8080/156500 PE+WOODGSZ9292/188900 PP+CaCo3Single screw pelleting extrusion unitsModelOutput capacity(kg/h)Applicable raw m

-

PVC Expansion Sheet Extrusion Line

PVC Expansion Sheet Extrusion LineModelGSZ65/132-GF800GSZ80/156-GY1220GSZ92/188-GY1600Thickness0.06-8mm0.06-25mm0.3-35mmWidth80012201600Main power37kw75kw110kwProduct typeblister sheets, edge banding, architectural plates.Capacity200kg/h400kg&s