Large Capacity of Corn Oil Corn Germ Oil Manufacturing Plant

Shenzhen Xiangfeizhu Technology Co., Ltd.- Voltage:380V

- Appearance:Vertical

- Press Materials:Rice

- Press Series:Fifth

- Condition:New

- Customized:Customized

Base Info

- Model NO.:HT-150

- Transport Package:Suitable for Shipping

- Specification:2100*280*1370mm

- Trademark:HUATAI

- Origin:Henan

- HS Code:84792000

- Production Capacity:30sets,Month

Description

Basic Info.

Model NO. HT-150 Transport Package Suitable for Shipping Specification 2100*280*1370mm Trademark HUATAI Origin Henan HS Code 84792000 Production Capacity 30sets/MonthProduct Description

Henan Huatai Cereals and Oils Machinery Company

Henan Huatai Cereals and Oils Machinery Co., Ltd, specialized in the design, manufacture and installation of all kinds of oil machinery and equipment. It is the national key manufacture enterprise for oil machinery complete sets of equipment. It is also an outstanding corporate member of Oil and Fat Division of CCOA (Chinese Cereals and Oil Association). We have obtained " Design License of Grade D1 & D2 Pressure Vessel ", "Manufacture License of Grade D1 & D2 Pressure Vessel", "Design License of Pressure Pipeline", "Installation License of Pressure Pipeline", "Manufacture and Installation license of Organic Heat Carrier Boiler", "Mechanical and electrical equipment installation project specialized contracting qualification" and "Work Safety License". Our company has always been to develop oil equipment modernization and internationalization for goal. We commit to research and develop the high and new technology of oil machinery. We have turned the latest scientific research results into productivity rapidly and achieved good social effects and economic returns for developing Chinese oil industry.

Henan Huatai Cereals and Oils Machinery Co. Ltd has fixed assets net output value of more than 120 million yuan, covers an area of 145 acres, of which the main plant area of 21,600M2, office and auxiliary building area of 14,449 M2, with a variety of advanced production and processing equipment more than 120 sets, lathes, planers, milling machines, drilling machines 80 sets, More than 10 sets of shearing forming equipment, including shearing capacity of 13*2500, coiling capacity of 20*2200 and plasma cutting equipment. There are 6 submerged arc automatic welding machines, more than 80 DC welding machines and AC welding machines. The auxiliary equipment include lifting equipment such as hanging cranes, gantry cranes and automobile cranes. The testing equipment has conventional measurement, leak test, universal material test and More than 30 sets of non-destructive testing, with an annual output value of 260 million yuan.

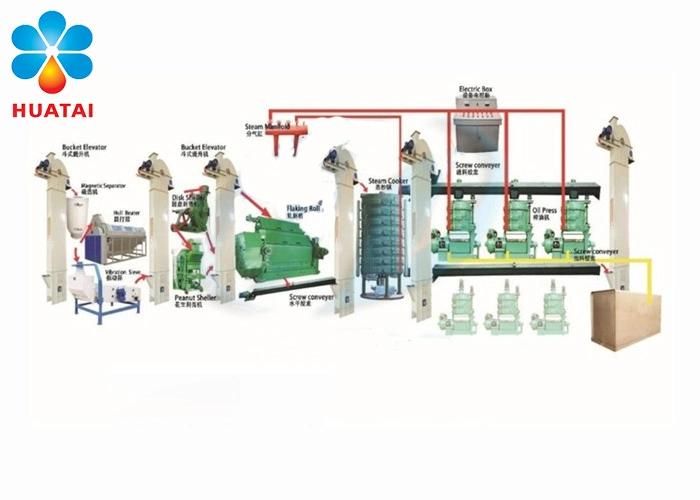

Corn Germ Oil making

Using corn as raw material, in the process of producing corn bran, corn starch or corn starch sugar, about 8%-12% of corn germ can be recovered, which can be used to prepare corn germ oil and corn germ protein.

The process, equipment and operation technology of corn germ oil are basically the same as those of other oil materials, and must be cleaned→ dried→ softened→ flaking→ cooking→ pressed→ refined and so on.

Corn gearm Cleaning

The corn germ recovered from corn grits is mixed with much corn flour, corn bran, and needs to be sieved with a double vibrating sieve. The first layer of screen removes large impurities, using 1.5 × 1.5 mesh / cm; the second layer removes corn flour, minced meat and dander, with 4 × 4 mesh / cm, if the sieve is still mixed more for the cuttings, you can use 5 × 5 mesh / cm or 7 × 7 mesh / cm to reduce the loss of corn germ. The corn germ recovered from corn starch is mixed with impurities such as dander and radicle sheath, and needs to be continuously rinsed several times with clear water by a shallow pan or a launder. For example, a factory equipped with a cyclone separator can be produced by using a swirling flow. Centrifugation separates the germ.

Drying

The corn germ recovered in the process of making corn grits and corn starches contains higher moisture content after cleaning, the enzyme activity is stronger and is easily propagated by microorganisms, which results in the deterioration and rancidity of oil esters, which affects the yield and quality of oil products. It will reduce the utilization value of the cake. In order to maintain the freshness of the corn germ during storage and transportation, the cleaned corn germ should be dried or dried immediately until the moisture content is below 10%.

Soften.

The first treatment of oil preparation for corn germ. The moisture content of the corn germ can be adjusted to below 10% while being heated, and the plasticity of the material germ can be changed, then the germ can be rolled into a certain thickness and not easily crushed. In order to prevent the protein from denaturing prematurely, and to make the material lose its elasticity, which affects the processing of rolling, cooking and press oil.

Flaking. After softening treatment, the corn germ is rolled into 0.3 mm-0.4 mm slices by Roller Mill, which leads to the destruction of the cell structure, shortening of the oil path, and being convenient for cooking and pressing of the material.

Cooking

The moisture content of the flaker is not less than 12% when the flaker is steamed and cooked in the cooker. After 40 minutes-50 minutes, the moisture content of the flaker is gradually reduced from 12% to 3%-4% when the temperature of the flaker is over 100 °, and you can smell it without burning it. During the whole process of steaming and cooking, the material is subjected to the double-action process of steaming and then frying, and at the same time, the moisture, temperature, plasticity and elasticity of the material are slowly regulated and controlled The destruction of the colloid structure of the denaturation and the decrease of the viscosity of the oil in the oil prepared the conditions for extracting the oil from the material.

Pressing. The methods of making oil and fat include pressing, extraction and water substitution. The equipment and production scale of the press method can be divided into screw press and hydraulic press. Since the production of corn germ oil is mostly carried out in a small scale and auxiliary workshop, it is suitable to use the screw press, which can be a production plant of a slightly larger scale, depending on the production scale, the screw press can be assembled with steaming and cooking equipment. Steam and cooking both, continuous operation, easy to use, steam and cook materials, oil in a group of equipment to complete. When the temperature of the steamed-cooked material is 115 °c-120 °C and the moisture content is 2%-4%, the material will be directly pressed into the press for oil. At this time, the room temperature should be kept at 30 °c-40 °C, the initial material input of the material is less, and the temperature of the press chamber will rise after the press is in normal operation Then evenly feed, oil and the cake output, can smell the cake aroma, cake solid, smooth surface, back crack, oil output normal. If steaming and cooking temperature is low, the material flaker moisture content is on the high side, the cake piece is soft, the water vapor is very thick, the oil color is not good, the white frothing, and the oil production reduces. If steaming and cooking temperature is too high, the flakers moisture content is too low, then the cake color is too dark, the export smoke and has a burnt taste, the oil color is deep, the oil output is also reduced. Normal operation of the press, the general oil press speed control for 8 RPM, material in the press chamber pressing time for 2.5 minutes, 5mm-6mm thickness of the cake. The yield of oil from corn grits is 22%-26%, the yield of oil from corn starch is 25%-28%, and the residual oil in corn cake is 5%-6%. The pressed oil, commonly known as crude oil without refining, contains 0.3% water and volatile matter, 0.2% impurities, 6% acid value, 6% precipitate, pale yellow color and normal smell, heated at 280 °C, The crude oil is not good for storage because of its high content of water and impurities. It needs to be refined by hydration, Alkali refining and deodorization to obtain high quality refined corn oil.

Corn Germ Oil refining

Advanced workshop appliance

Various Certificates and honor Certificate of Huatai

Oversea Projects of Henan Huatai

| No. | Country | Project Nam |

| 1 | Australia | 150T/D Vacuum Drying Equipment |

| 2 | Australia | 100T/D High Material Layer Desolventizer |

| 3 | Bangladesh | 30T/D Rice Bran Making Oil Project |

| 4 | Bangladesh | 100T/D Rice Bran Making Oil Project |

| 5 | Bangladesh | 30TPD Sunflower Seed, Mustard Seed Making Oil Project,30T/D Fully Continuous Oil Refining Project |

| 6 | Banglades | 15T/D Rapeseed Oil Refining Project |

| 7 | Bolivia | 60T/D Soybean Oil Refining Project |

| 8 | Cambodia | 30T/D Rice Bran Making Oil Project |

| 9 | Cameroon | 5T/D Palm Oil Stirring Tank |

| 10 | Congo | 0.5T/H Palm Oil Making Soap Project |

| 11 | Congo | 400T/D Peanut Making Oil Project |

| 12 | Congo | 15T/H Palm Fruit Pressing, 10T/H Palm Oil Refining and Fractionation Project |

| 13 | Congo | 5T/H Palm Fruit Pressing, 5T/D Palm Oil Refining Project |

| 14 | Djibouti | 2T/D Sunflower Oil Dewaxing Machine |

| 15 | Ethiopia | 50T/D Soybean Oil Refining Project |

| 16 | Ethiopia | 100T/D Corn Processing Project |

| 17 | Ethiopia | 15T/D Peanut and Sunflower Seeds Pressing,5T/D Oil Refining Project |

| 18 | Ethiopia | 5T/D Crude Oil Refinery Project |

| 19 | Ethiopia | 250T/D Flax Seed Oil Making Project |

| 20 | Ethiopia | 50T/D Soybean/Peanut oil press and 30T/D Oil Refining Project |

| 21 | Ethiopia | 15T/DSoybean/Peanut oil press and 10T/D Oil Refining Project |

| 22 | Ethiopia | 200T/D Palm oil Deacidification &Deodorization,100T/D Palm Oil Fractionation Project |

| 23 | Ethiopia | 50T/D Sunflower/Cotton Seed,Sesame Oil Press and 20T/D Oil Refining Project |

| 24 | Egypt | 100T/D Soybean Pretreatment and Extraction Project |

| 25 | Egypt | 20T/D Soybean Oil Refining Project |

| 26 | Egypt | 10T/D Cottonseed Oil Refining Project |

| 27 | Estonia | 10T/D Biodiesel Distillation Project |

| 28 | Ghana | 20T/D Corn Flour Production Line Project |

| 29 | Indonesia | 20T/D Coconut Oil Pressing,10T/D Oil Refining Project |

| 30 | Indonesi | 3T/D Fragrant Sesame Oil Project |

| 31 | Indonesi | 3T/D Oil Refining Machine |

| 32 | Indonesia | 20T/D Maize germ oil pressing and 5T/D oil refining project |

| 33 | Kazakhsta | 3T/D High-class Cooking Oil Refining Project |

| 34 | Kazakhsta | 120T/D Sunflower Seed Prepressing, Extraction and Refining Project |

| 35 | Kazakhsta | 50T/D Safflower Oil Processing Project |

| 36 | Kazakhsta | 100T/D Soybean Pretreatment ,Oil Press Project |

| 37 | Kenya | 3T/D Pyrethrin Extraction Project |

| 38 | Malaw | 2T/D Oil Refining Machine |

| 39 | Moldov | 3T/D Sunflower Oil Refining&dewaxing Machine |

| 40 | Myanma | 3T/D Cottonseed Oil Refining Machine |

| 41 | Myanmar | 5T/D Oil Refining Project |

| 42 | Nigeria | 5T/H Palm Fruit and Kernel Pressing Project |

| 43 | Nigeria | 20T/D Palm Oil Refining and Fractionation Project |

| 44 | Nigeria | 50T/D Peanut Pressing, 15T/D Peanut Oil Refining Project |

| 45 | Nigeria | 40T/D Cotton Seed Oil Processing and 15T/D Oil Refining Project |

| 46 | Nigeria | 60T/D Soybean,Peanut,Shea nut Oil Press ,25T/D Oil Refining Project |

| 47 | Peru | 50T/D Cotton Seed Palm Oil Refining Project 50T/D/ |

| 48 | Peru | 50T/D Palm Oil Refining and Fractionation Project |

| 49 | Peru | 150T/D Soybean/Palm/Sunflower Oil Refining Project |

| 50 | Russia | 50T/D Soybean Pretreatment, 50T/D Solvent Extraction and 10T/D Soybean Oil Project |

| 51 | Russia | 10T/D Rapeseed Oil Pressing Project |

| 52 | Russia | 10T/D Sunflower/Rapeseed Oil Pressing and 3T/D Oil Refining Project |

| 53 | Rwand | 10T/D Palm Oil Refining Project |

| 54 | Solomon Island | 3T/D Coconut Oil Deacidification & Deodorization Project |

| 55 | Sri Lank | 30T/D Chicken Oil Pressing, 20T/D Chicken Oil Refining Project |

| 56 | Sri Lank | 5T/D Fish Oil Refining Project |

| 57 | Sudan | 30T/D Peanut Oil Pressing, 15T/D Peanut Oil Refining Project. |

| 58 | Swaziland | 30T/D Oil Refining Machine |

| 59 | Tajikista | 50T/D Cottonseed Cake Extraction Project |

| 60 | Tajikista | 50T/D Cottonseed Pre-pressing Project |

| 61 | Tanzania | 20T/D Sunflower Seeds Pressing, 5T/D Refining Project |

| 62 | Tanzania | 10T/D Sunflower Seeds Pressing, 3T/D Refining Project |

| 63 | Thailand | 10T/H Palm Oil Renovation Project |

| 64 | Thailand | 45T/H Palm Fruit Sterilization Tank |

| 65 | Thailand | 2T/D Palm Oil Refining Project |

| 66 | Philippines | 30T/D Corn Germ Pressing and Refining Project |

| 67 | Philippines | 15T/D Corn Processing Project |

| 68 | Turkmenistan | 50T/D Sunflower Seed Pretreatment,30T/D Extraction and 20T/D Refining Project |

| 69 | Ukraine | 30T/D Sunflower cake Extraction Project |

| 70 | Ukraine | 50T/D Sunflower cake Extraction Project 50T/D |

| 71 | Uzbekistan | 80T/D Sunflower Seed Cake Extraction,50T/D Sunflower Oil Refining Project |

| 72 | Uzbekistan | 50T/D Sunflower Seed,Soybean,Cottonseed Making Oil Project |

| 73 | Uzbekistan | 100T/D Sunflower Seed Prepressing, Soybean Pretreatment, 100T/D Micro-negative Pressure Extraction and 20T/D Grade 1 Oil Refining Project |

| 74 | Uzbekistan | 100T/D Sunflower Seed Cake Extraction,30T/D Semi-cotinuous Sunflower Seed Oil Refinery and Dewaxing Project |

| 75 | Uzbekistan | 100T/D Sunflower Seed Cake Extraction,50T/D Sunflower Seed Oil Refinery Project |

| 76 | Uzbekista | 30T/D Sunflower Seed Oil Processing 10T/D Oil Refining Project |

| 77 | Uzbekistan | 100T/D Sunflower Seed Oil Processing 80T/D Extraction Project |

| 78 | Uzbekistan | 50T/D Sunflower Seed Pre-press, 50T/D Extraction and 30T/D Refining Project |

| 79 | Uzbekistan | 20T/D Sunflower Cake Extraction,2T/D Sunflower Oil Refinery Project |

| 80 | Uzbekistan | 40T/D Sunflower and Cottonseed Oil Dewaxing Project |

| 81 | Uzbekistan | 50T/D Sunflower Seed,soybean Pre-press, 50T/D Extraction and 20T/D Refining Project |

| 82 | Uzbekistan | 30T/D Sunflower Seed Pre-press, 20T/D Extraction and 10T/D Refining Project |

| 83 | Uzbekistan | 100T/D Sunflower Seed Pre-press, 80T/D Extraction and 40T/D Refining and Dewaxing Project |

| 84 | Uzbekistan | 80T/D Sunflower Cake ,Soybean Flakers Extraction Refining Project |