PVC Crust Foam Board Extrusion Lmaking Line Machinery (SJSZ-80/156)

Ningbo Zhaoke Int'l Imp. & Exp. CorpBase Info

Description

Basic Info.

Model NO. SJSZ80/156 Certification CE, ISO9001:2008 Customized Customized Condition New Material Stailness Steel Mould for Sheet/Board T Type Button Schneider Inverter ABB Intelligent Temperature Controller Omron Operator 2-3person /Shift After Sale Service Life Long with Professional After Sale Team Machine Color as Request Raw Material PVC Powder Transport Package as Export Standard for Plastics Machine Specification ISO9001 CE Trademark SUKE Origin Qingdao China HS Code 84775900 Production Capacity 50sets/YearProduct Description

PVC Crust Foam Board Extrusion LMaking Line Machinery (SJSZ-80/156)FOAM BOARD INTRODUCTION:

Free Foam PVC Board is manufactured using Free Foam Extrusion. Free Foam PVC Board has a consistent cell structure and density from surface to core that performs well in advertising applications. The cell structure makes it the choice for professional printers, sign makers and exhibition contractors.

.

FOAM BOARD APPLICATION:

Construction;

Advertisement( printing, computer lettering, carving etc. );

Signage;

POP;

Cupboard(kitchen);

Furniture board;

Marine;

Water park;

Seashore wet-proof facility;

Various interlayer;

Decoration board, upholstery, mould plate for train, car and many more.

MACHINE SPECIFICATION:

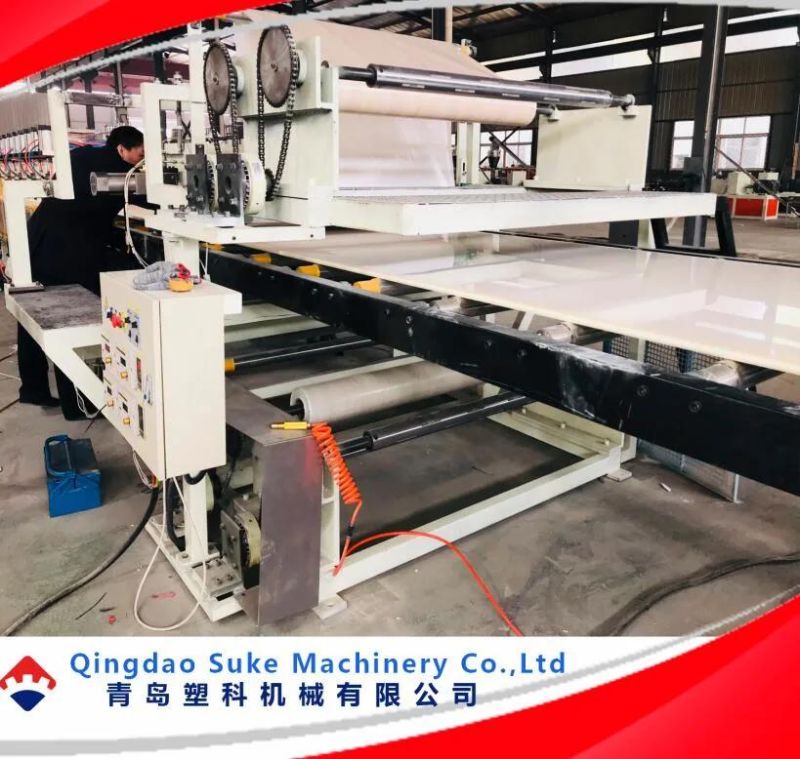

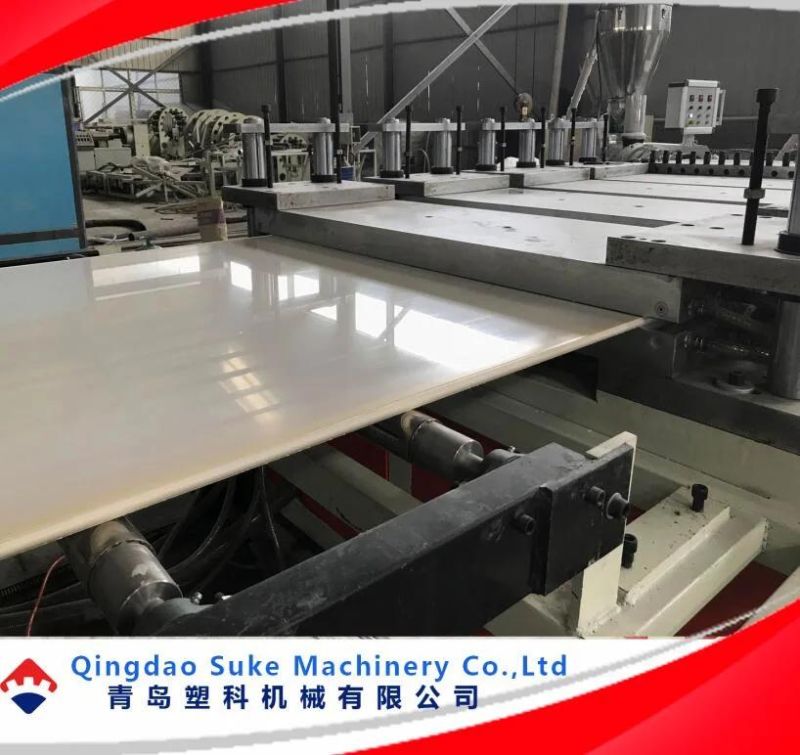

Standard board size is 1220mm*2440mm(48"*96");

Thickness 1mm, 2mm, 3mm, 4mm, 5mm, 6mm;

Densities from 0.42-0.8g/cm3;

Surface: Matte/matte finish;

Colours: Available in White, Custom colours - 3mm, 5mm.

Size: 1560mm*3050mm and 2050mm*3050mm;

Thickness 1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm;

Densities from 0.55-0.90g/cm3;

Surface: Matte/matte finish;

Colors: Available in White.

MACHINE TYPE:

Model | SJP120/21-1500 | SJZ85/156-1150 |

| Product width | 2050mm | 1220-1560mm |

| Product thickness | 0.6-1.5mm | 0.5-3mm |

| Extruder specification | SJP120/21 | SJZ85/156 |

| Main motor power | 132KW | 90KW |

| Max. Extrusion capacity | 500Kg/h | 300Kg/h |

EQUIPMENT LIST:

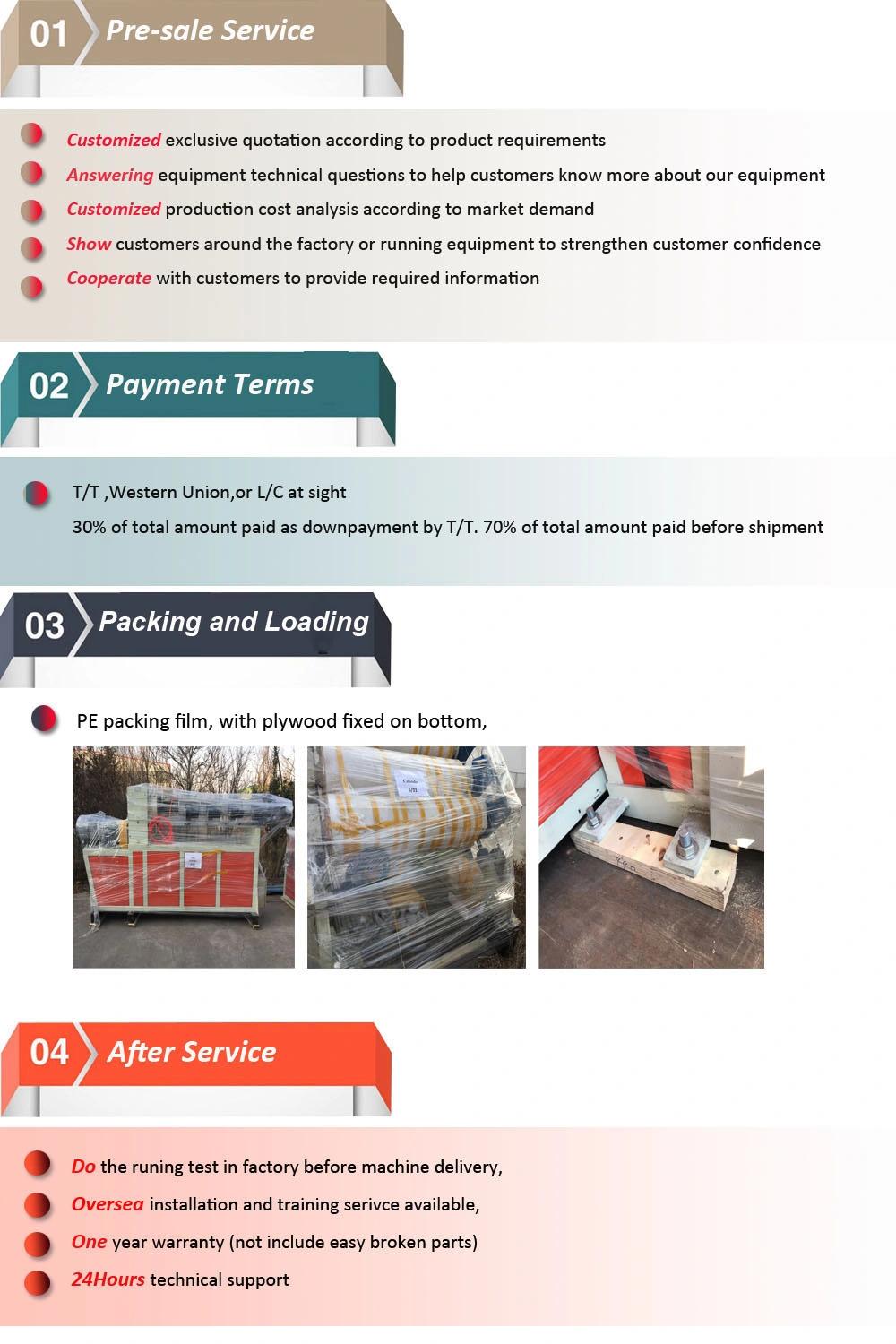

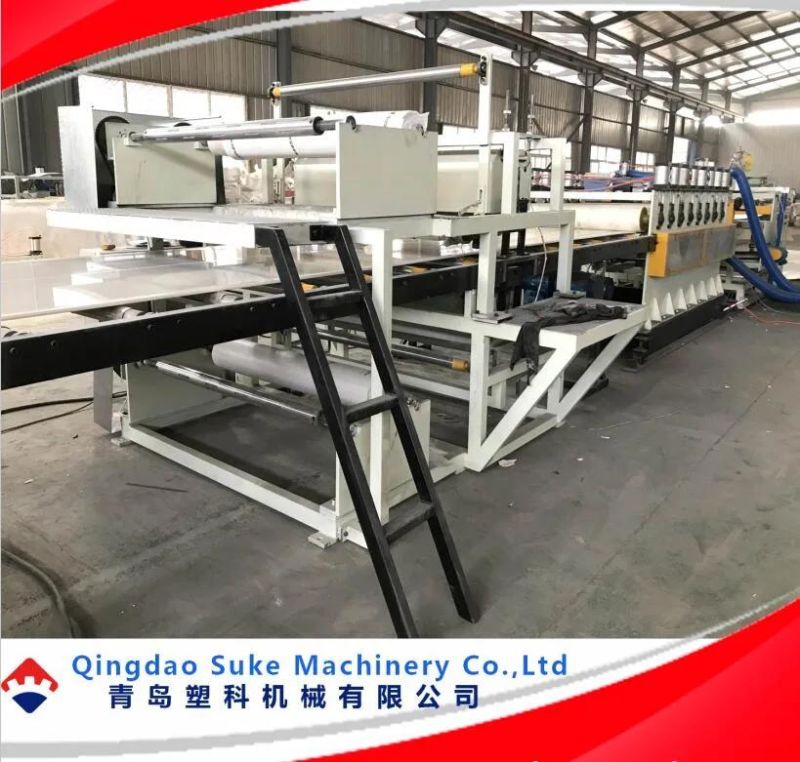

- Double Screw Extruder 1 unit

- Mould 1 set

- Shaping Machine 1 unit

- Haul-off Machine 1 unit

- Cutting Machine 1 unit

- Stacker 1 unit

- Crusher 1 unit

- Mixer 1 unit

- Pulverizer 1 unit

- Air Compressor 1 unit