SUS304 1000L Conical Fermenter Beer Machine with Dimple Cooling Jacket

Jinan Jotop Import and Export Trade Co., Ltd.- Processing Material:Natural Ingredients, Water Malt Yeast Hops

- Application:Beverage, Beer, Cerveza, Tea, Beer Brewing, Brasserie

- Customized:Customized

- Certification:CE, UL, ISO9001

- Power Source:Steam , Electric , Fire

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:MT-1000L FT

- Condition:New

- Voltage:220V, 380V

- Material:Full Stainless Steel SUS304

- Welding:Arc Argon Protection

- Warranty:3 Years for Tank

- After Sales Service:Installation and Equipment Commission

- Technology:Offer Auto CAD and 3D Design Drawing

- Material Thickness:Inner Wallet 3mm outer Wallet 2mm

- Fermenter:Double Wallet with Dimple Cooling Jacket

- Cooling Unit:Chiller with Glycol Tank

- Control Unit:Temp. Controller, HMI , PLC or Touching Screen

- Insulation:Polyurethane Foam

- Polish Finish:0.4-0.6um

- Surface Finish:Brushed , Mirror , Pickled SUS304 or Copper

- Electric Elements:up to Ce UL Standard

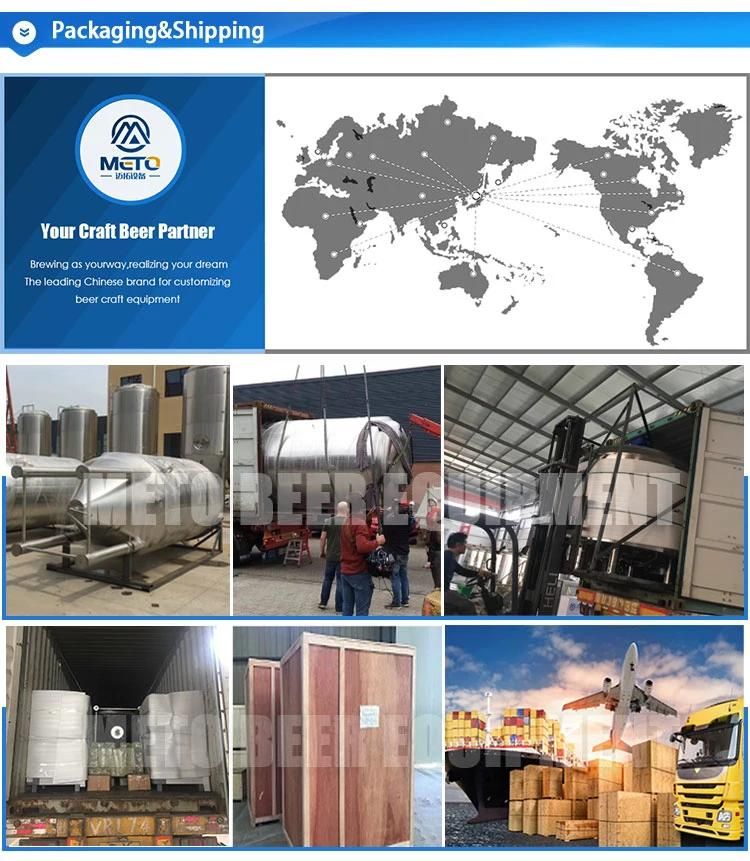

- Transport Package:Plywood Case by LCL or Container by FCL

- Specification:Customized

- Trademark:METO

- Origin:Jinan, China

- HS Code:8438400000

- Production Capacity:20 Sets Per Month

Description

Beer FermenterMaterial: SUS 304, SUS 316 Thickness of material Interior Shell: 3mm/4mm, can be customized

Exterior Shell: 2mm/3mm, can be customized Insulation Polyurethane-thickness: 80mm Cooling jacket Dimpled plate on cone and side Cooling media Alcohol water or glycol water. Spare Parts Full sanitary sample valve;

Equip with Electromagnetic valve;

Shockproof pressure gauge on CIP arm;

Safety valve on fermenter top;

Tri-clamp discharge arm with butterfly valve;

Dry hopping port with hops adding device;

CIP arm with 360°coverage CIP spraying ball;

Thermowell with high accuracy temperature sensor: PT100

Ice water pipe: PPR or stainless steel pipe as option;

With ice water pipe insulation;

Carbonation device for CO2 is option; Manufacture Arts 100% TIG welding with pure argon gas shield;

Interior Finish: Overall polishing to 0.4~0.6μm with passivation finish. Type Size Total Capacity Para 100L φ620×1900 147L Top manhole (external opening) 200L φ820×1700 260L Top manhole (external opening) 300L φ860×2100 375L Top manhole (external opening) 500L φ1060×2200 720L Top manhole (internal opening) 600L φ1160×2300 750L Top manhole (internal opening) 1000L φ1260×2750 1320L Side manhole 1500L φ1460×3000 1880L Side manhole 2000L φ1560×3000 2500L Side manhole 3000L φ1760×3850 3800L Side manhole 4000L φ1900×4000 5130L Side manhole 6000L φ2000×4800 7500L Side manhole 10000L φ2200×6000 12500L Side manhole 3BBL φ910×2050 4BBL Top manhole (external opening) 5BBL φ1060×2250 6BBL Top manhole (internal opening) 7BBL φ1160×2300 9BBL Top manhole (internal opening) 10BBL φ1360×2500 15BBL Side manhole 15BBL φ1460×3000 23BBL Side manhole 20BBL φ1660×3300 29BBL Side manhole 30BBL φ1660×3300 46BBL Side manhole 40BBL φ1760×3600 50BBL Side manhole 50BBL φ2200×4500 62BBL Side manhole 60BBL φ2200×4900 75BBL Side manhole 80BBL φ2200×5800 100BBL Side manhole 100BBL φ2200×6300 125BBL Side manhole

4. Packing & shipping

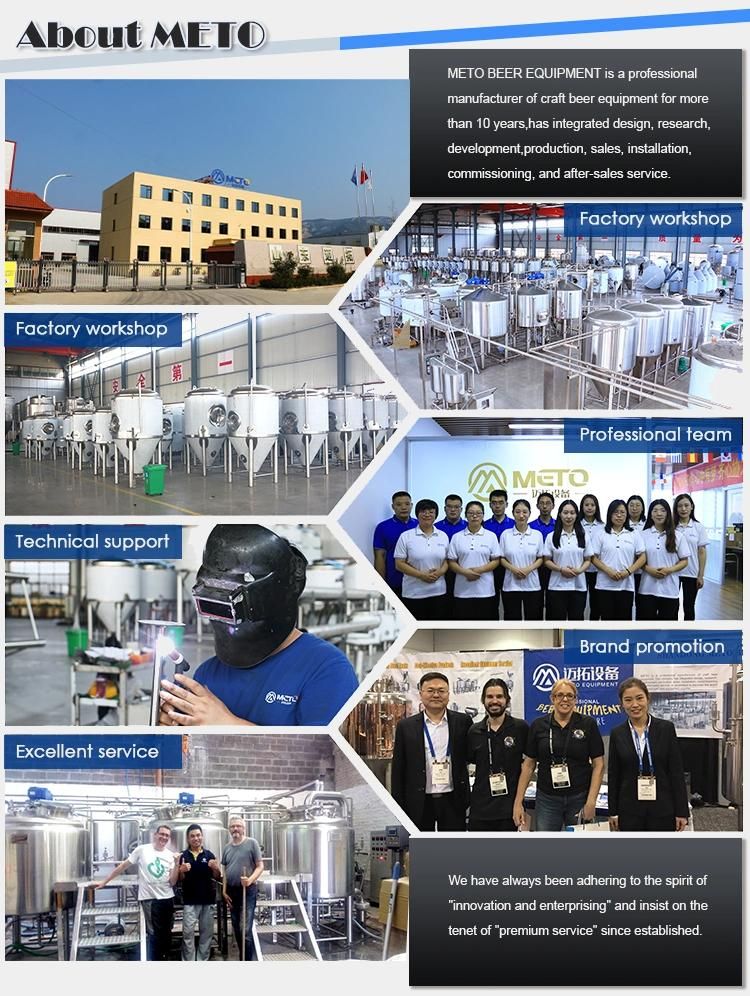

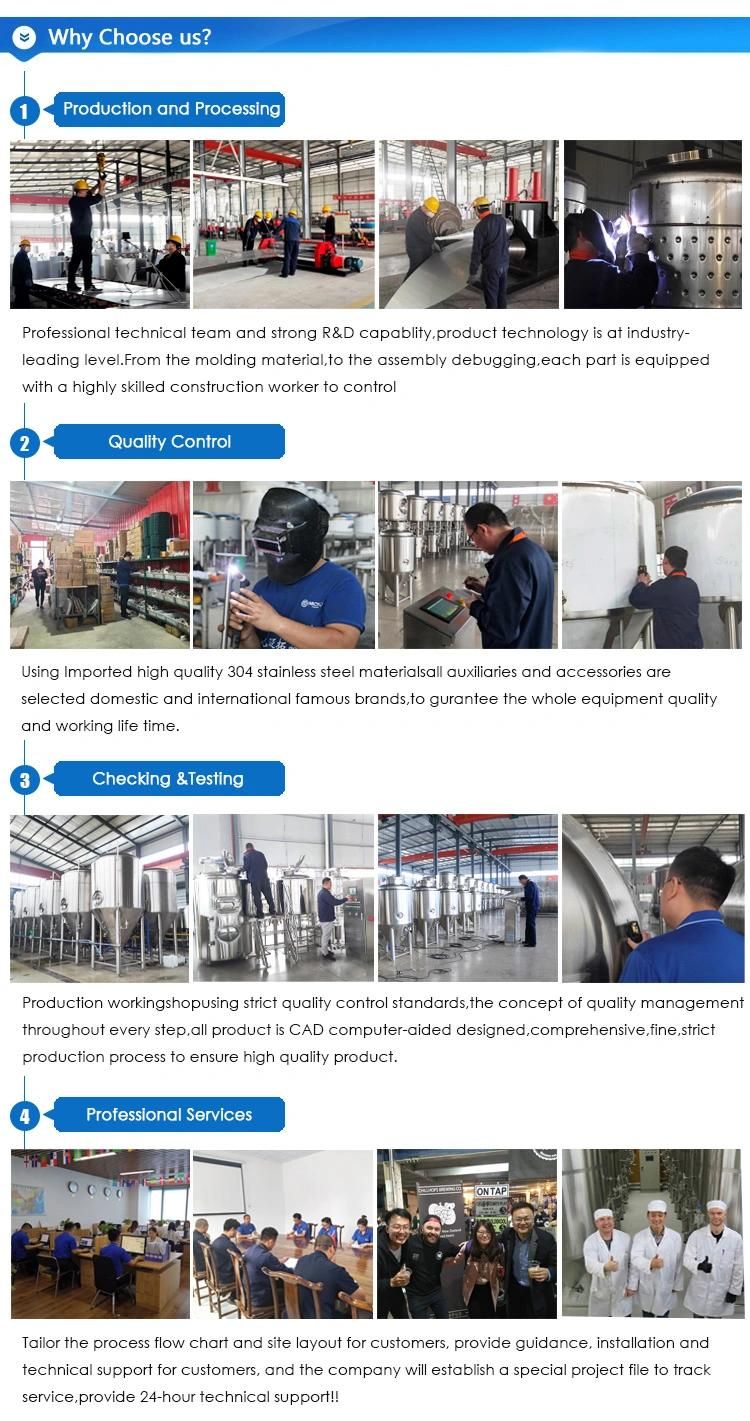

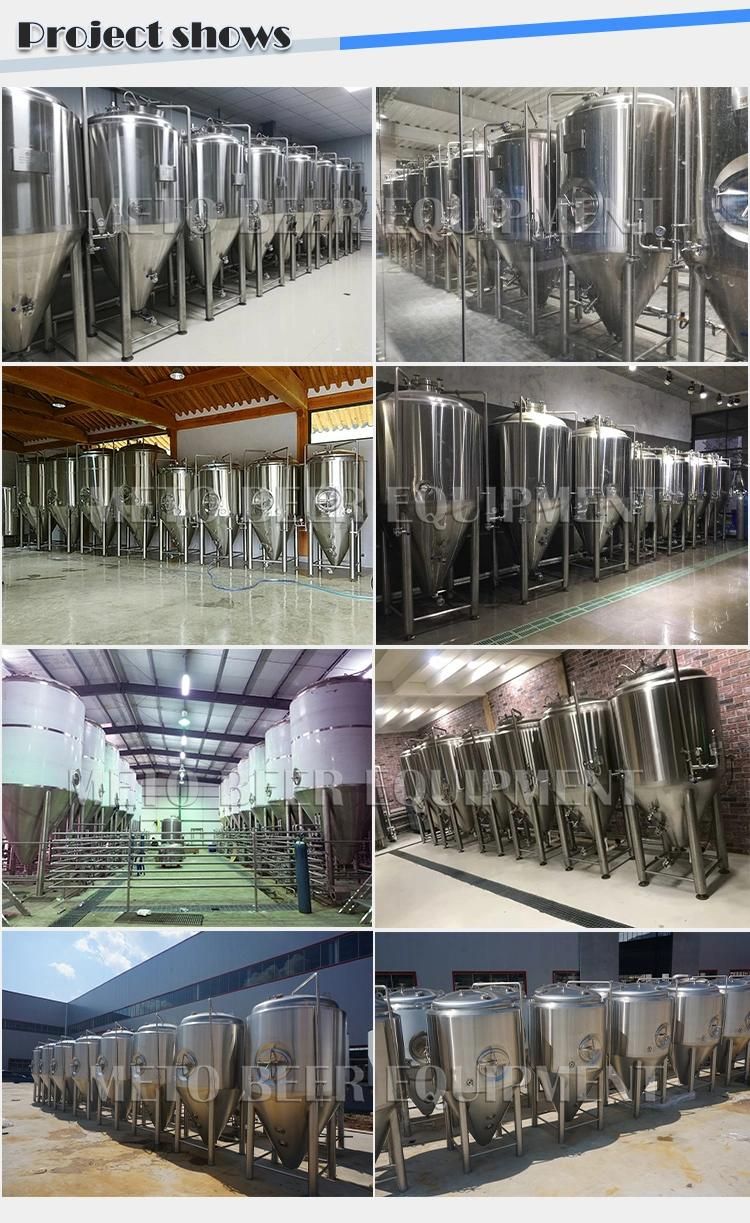

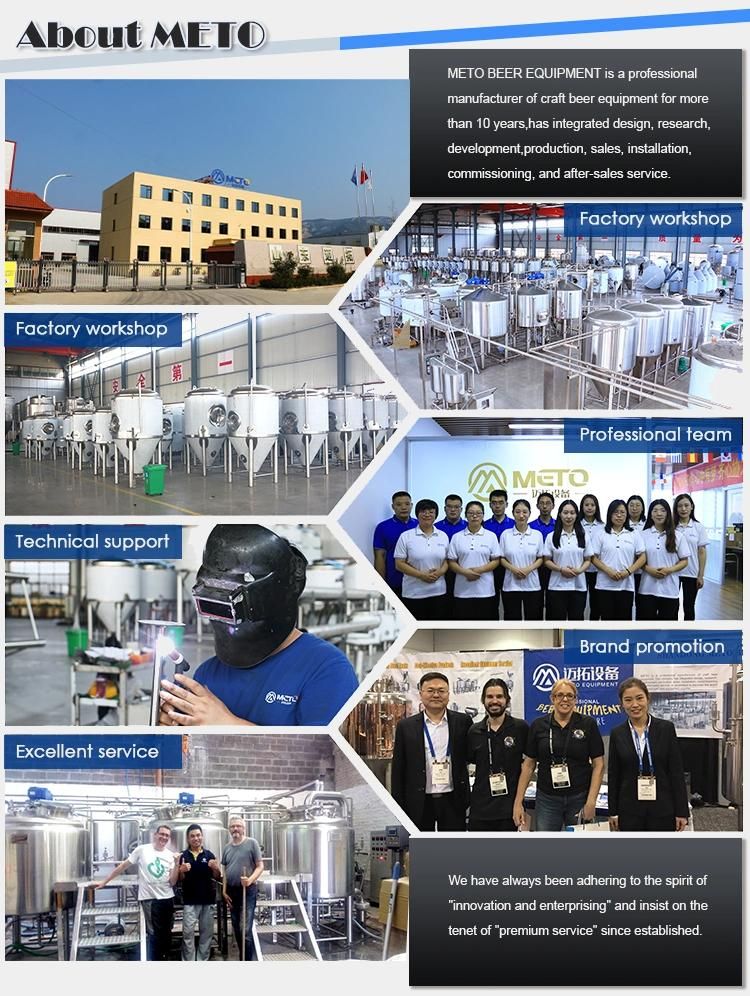

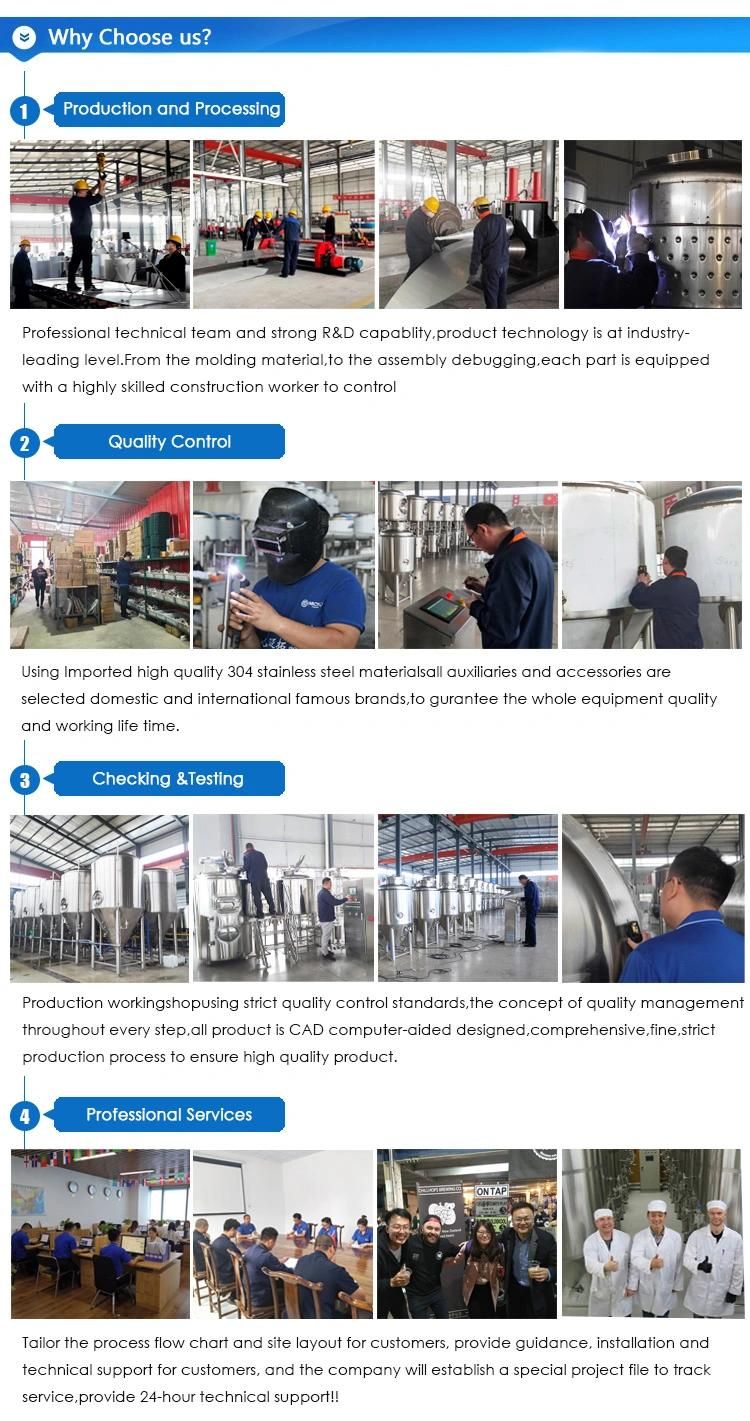

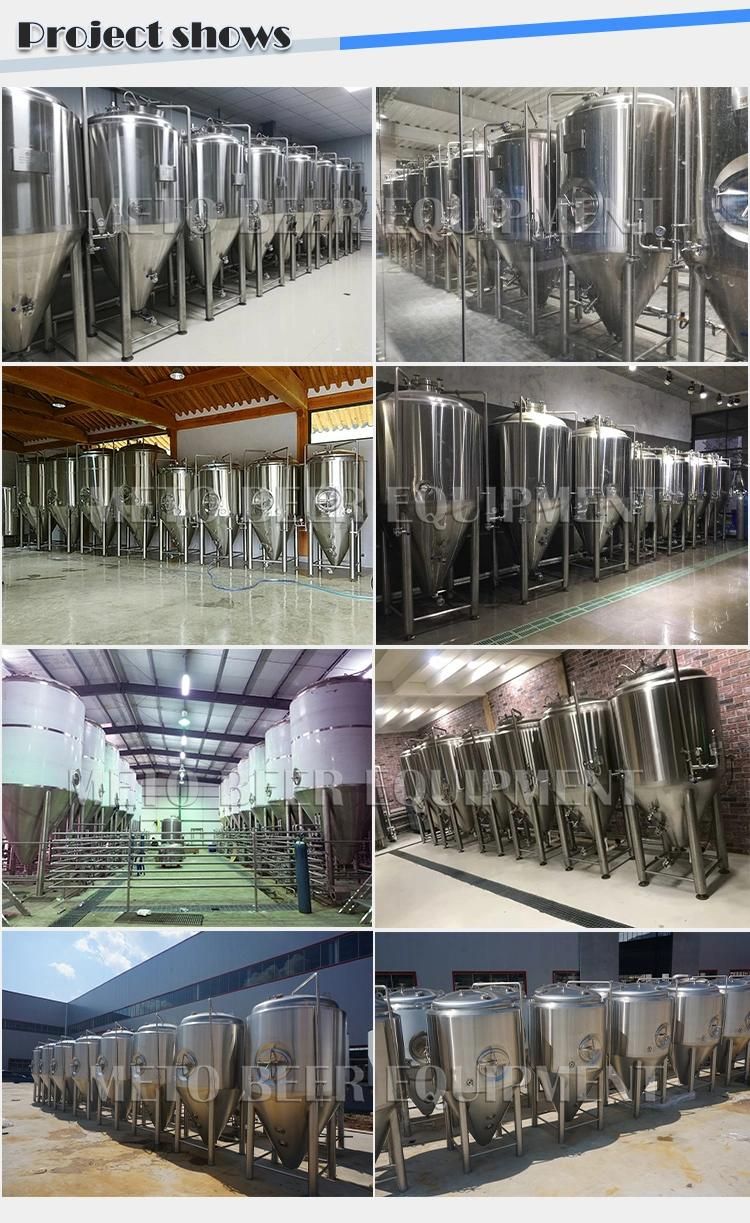

5. Company Introduction

Exterior Shell: 2mm/3mm, can be customized

Equip with Electromagnetic valve;

Shockproof pressure gauge on CIP arm;

Safety valve on fermenter top;

Tri-clamp discharge arm with butterfly valve;

Dry hopping port with hops adding device;

CIP arm with 360°coverage CIP spraying ball;

Thermowell with high accuracy temperature sensor: PT100

Ice water pipe: PPR or stainless steel pipe as option;

With ice water pipe insulation;

Carbonation device for CO2 is option;

Interior Finish: Overall polishing to 0.4~0.6μm with passivation finish.

4. Packing & shipping

5. Company Introduction