High Quality Semi-Continuous Plastic Waste Oil Distillation Pyrolysis Plant

CNBM MATERIAL CO., LTD.Base Info

Description

NoSpecification Fully continuous waste tyre/plastic/rubber prolysis plant 1 Model BH-FC30 BH-FC40 BH-FC50 BH-FC60 2 Working type Fully continuous Fully continuous Fully continuous Fully continuous 3 Raw Material Waste tires,waste rubber,waste plastic,waste acrylic,oily sludge 4 24 hour handling capacity 30T 40T 50T 60T 5 24 hour oil production 14T 18T 22T 27T 6 Heating way Directly heating Directly heating Directly heating Directly heating 7 Working pressure Ordinary pressure Ordinary pressure Ordinary pressure Ordinary pressure 8 Cooling way Water cooling Water cooling Water cooling Water cooling 9 Water consumption 10T/H 12T/H 16T/H 20T/H 10 Noise ≤85DB(A) ≤85DB(A) ≤85DB(A) ≤85DB(A) 11 Total weight 60T 68T 75T 80T 12 Area 47*10*9M 53*10*9M 55*10*9M 58*10*9M

(pyrolysis machine included)

*extra gas also be storage as fuel for other heating.Our Advantages1. Security:

a: Adopting automatic submerged-arc welding technologyb: All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the

welding shape.c: Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.d: Equipped with anti-explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming

system.

2. Environmental-friendly:

a: Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smokeb: Smell during operation: Fully enclosed during the operationc: Water pollution: No pollution at all.d: Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be deep-processed or sold

directly with its value.workshop

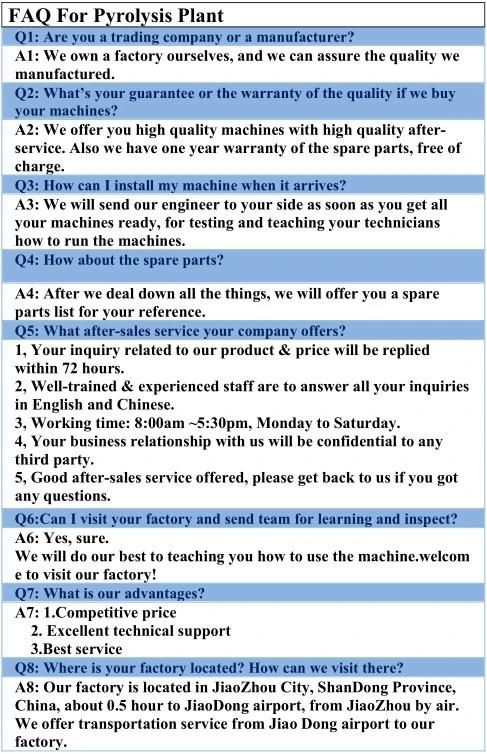

Why Choose Us

Our service

Our service

1.Quality warranty period: One year warranty for the main reactor

of pyrolysis machines and lifetime maintenance for complete set of machines.

2.Our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's

workers on operation, maintenance, etc.3. Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.4. For the damage caused by the users, our company provides the parts and accessories with cost price.5. Our factory supplies the wearing parts with the cost price to clients.

(pyrolysis machine included)

*extra gas also be storage as fuel for other heating.Our Advantages1. Security:

a: Adopting automatic submerged-arc welding technologyb: All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the

welding shape.c: Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.d: Equipped with anti-explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming

system.

2. Environmental-friendly:

a: Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smokeb: Smell during operation: Fully enclosed during the operationc: Water pollution: No pollution at all.d: Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be deep-processed or sold

directly with its value.workshop

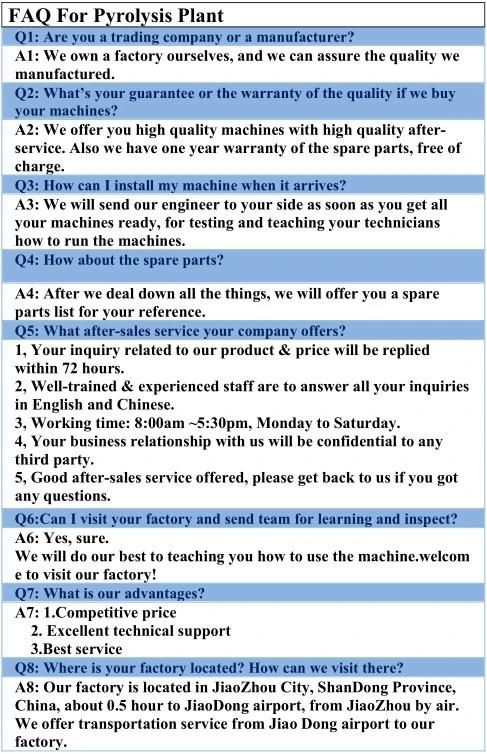

Why Choose Us

Our service

Our service

1.Quality warranty period: One year warranty for the main reactor

of pyrolysis machines and lifetime maintenance for complete set of machines.

2.Our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's

workers on operation, maintenance, etc.3. Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.4. For the damage caused by the users, our company provides the parts and accessories with cost price.5. Our factory supplies the wearing parts with the cost price to clients.