Sanitary SS316L Solid Liquid Mixing Pump Blender with Hopper

Jiangyin Yingcheng Packaging Technology Co., Ltd.- Condition:Used

- Customized:Customized

- Voltage:380V

- Composition:Filling Machine

- Processing Material:Natural Ingredients

- Process:Thermal Processing

Base Info

- 60, 000L/H:24m

- Motor Power:15kw

- Connection Way:Clamp or Thread

- Optional:Manual or Pneumatic Valve

- Transport Package:Plywood Case

- Specification:capacity: 10~60T Lift: 20M~24M

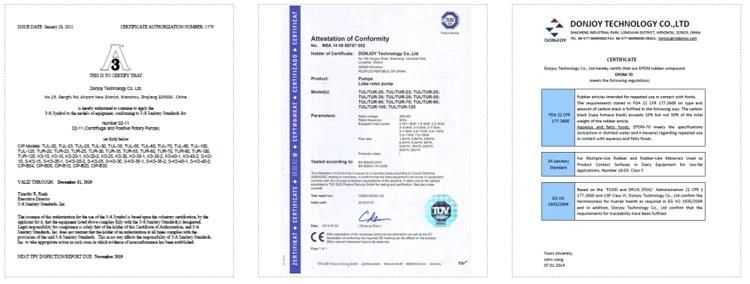

- Trademark:Donjoy

- Origin:Wenzhou, Zhejiang, China

- HS Code:8413810090

- Production Capacity:100PCS,Month

Description

Basic Info.

60, 000L/H 24m Motor Power 15kw Connection Way Clamp or Thread Optional Manual or Pneumatic Valve Transport Package Plywood Case Specification capacity: 10~60T Lift: 20M~24M Trademark Donjoy Origin Wenzhou, Zhejiang, China HS Code 8413810090 Production Capacity 100PCS/MonthProduct Description

The mixer / mixing pump can be used in mixing of a variety of materials, such as: Preparation of syrup, sorbitol, glucose, derivatives of lactose, preparation of powdered milk, dissolving cocoa or sugar in the milk, preparation of whey, preparation of flour and starch, preparation of salt water, premixed yogurt and other dairy desserts, dissolution of bentonite used for wine filtration, soluble casein and cheese making industry in the casein, preparation of pesticides and fertilizers.Flow: From 10m³ /h to 60m³ /h

Motor power: From 3kw to 15 kw

Frequency: 50Hz or 60Hz

Solids suction: 2000kg to 9000kg

Connection way: Tri-clamp / thread / Flange, DIN/SMS/3A/RJT/ISO/IDF

Design and features:

Simple and versatile assembly for quick and homogeneous mixing of a great variety of solids without contact with the air. Complete mixing with recirculation of the material. In some applications, itcan be used in line, without recirculation.

3A Sanitary design.

Easy assembly and disassembly by Clamp connections.

Cleaning can be carried out without disassembling the unit.

Sanitary single mechanical seal

Options:

Double cooled seal.

Connections: DIN, SMS.

Pneumatic actuator valve.

60o hopper.

Screen in the mixing chamber.

Drainage.

The following control components can be added:

Pneumatic valve.

High- and low-level sensors.

Vibrator (pneumatic or electric).

| Model | Description | Size(flow, head, motor) | Material |

| HHQ-20 | Material mixture pump | 20T/24M/4kw | 304 |

| HHQ-30 | Material mixture pump | 30T/24M/5.5kw | 304 |

| HHQ-40 | Material mixture pump | 40T/24M/7.5kw | 304 |

| HHQ-50 | Material mixture pump | 50T/24M/11kw | 304 |

| HHQ-60 | Material mixture pump | 60T/24M/15kw | 304 |