850ton Injection Molding Machine, Stable Quality, Competitive Cost, Save Energy, High ...

Henan Horn Tools Co., Ltd.Base Info

Description

Basic Info.

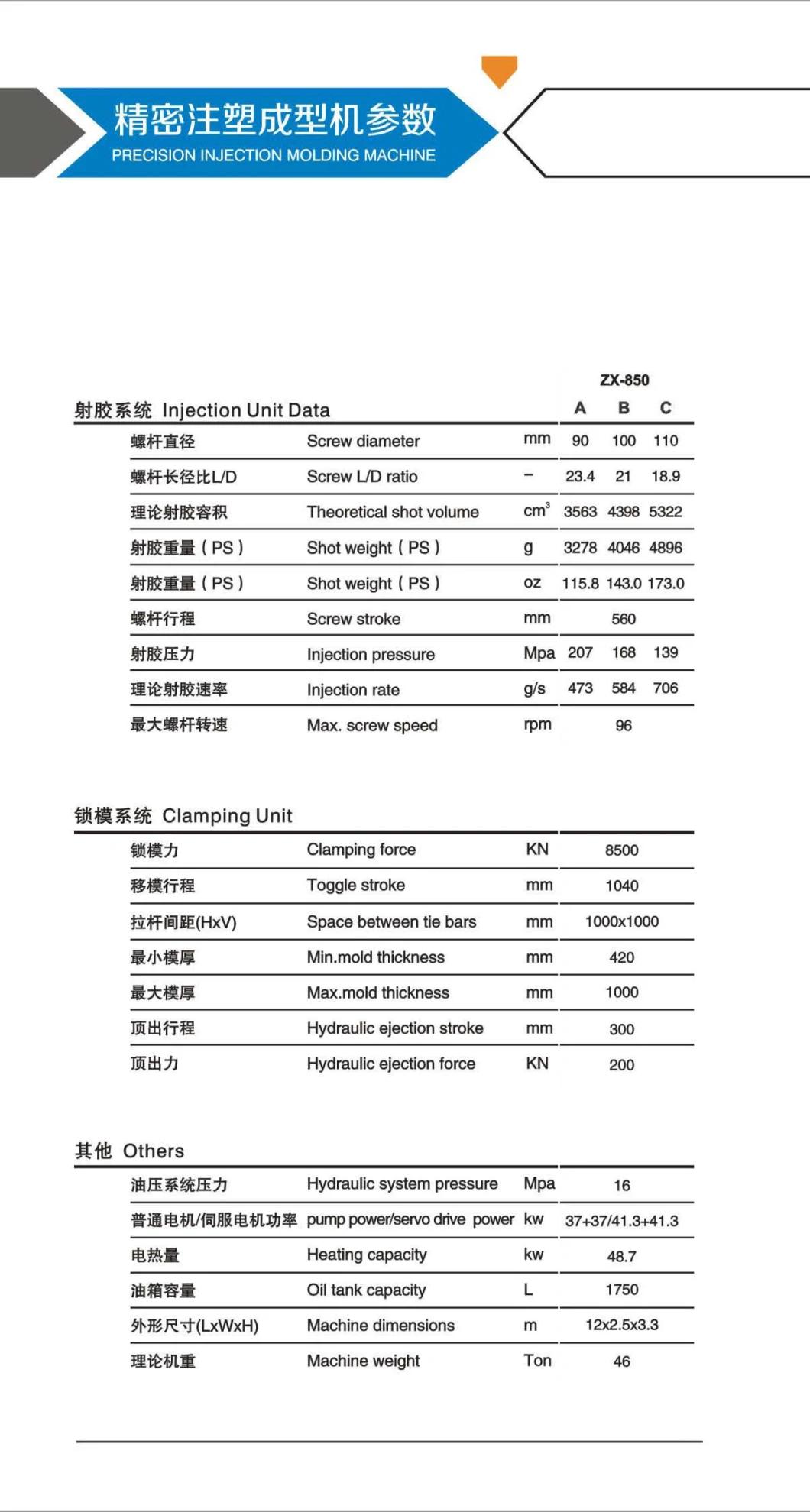

Model NO. ZX-850 Computerized Computerized Certification CE, ISO9001:2008 Motor Type Servo Motor Injection Weight 3278-4896g Space Between Tie Bars 1000 X 1000 mm Product 1 Household Production, Example Crate/Fork/Toy/Cover Product 2 Industrial Production, Example, Pipe-Fitting Product 3 Other Production, Example Medical/Agricultural Feature Stable Quality, Competitive Cost, Careful Service Transport Package Plastic Film Cover, Wood Pad, Wrapped Film Specification 12 x 2.5 x 3.3 M Trademark OEM Origin China HS Code 8477101090 Production Capacity 10PCS/MonthProduct Description

Standard Injection Molding Machine ZX-850

1, Standard Injection Molding Machine ZX-850 Introduction

The injection molding machine enjoy good reflection from the customers, and own the advantages as follows,

1) Precision: optimized mechanical structure with famous brand controller, greatly increase machine precise.

2) Stable: dual cylinder injection, perform stability and reliability.

3) Durable: platen with DFA design helps to strengthen the rigid

4) Energy Saving: comparing with traditional fixed pump or variable pump machine, it saves electricity obviously.

2, Standard Injection Molding Machine ZX-850 Parameter (Specification)

3, Standard Injection Molding Machine ZX-850 Feature And Application

4, Standard Injection Molding Machine ZX-850 Detail

1) High torque oil motor pre-plasticizing drive

2) Five fulcrum and double bent axle locking mould

3) Oil motor drive gear adjusting mould

4) automatic lubrication system

5) Pressure, flow precision running

6) High quality oil pump

7) Injection many stages pressure, speed adjusting

8) Chinese and English computer controlling

9) Mould group data memory function

5, Standard Injection Molding Machine ZX-850 Quality Qualification

The equipment according to the enterprise standard implementation. And the enterprise owns rich experience in field of plastic injection molding machine.

6, Technical and After-sales Service

The supplier the following technical and after-sales service commitment

1) English Technical files provided.

2) Machine tested before the delivery.

3) Technical support online service provided.

4) Consumable parts at reasonable price when replaced.

5) spare parts provided with each new machine

7, FAQ

1) Delivery time: within 7 days if in stock. It is subject to confirmation.

2) Packing: simple package

3) Trade Term: FOB, CFR, CIF, ect. It is subject to confirmation.

4) Default power system: 380V, 50Hz, 3Phase

8, Contact Information

Contact Person: Mr. Tony

Comapny: Ningbo Zhen Yue Machinery Co.,Ltd.

Address: No.39, Lane 158, Huangcheng West Road, Ningbo, China.

Zip Code: 315012

Product: Plastic Injection Molding Machine

9, Remark:

All the information (including words, photos, specification, figures, design) above are only for reference. It is subject to confirmation. The company reserves the right to revise all information (including words, photos, specification, figures, design) above.