Ce Turnkey Grain Puffed Corn Snacks Food Making Manufacturing Plant

Xiamen Hongxincheng Rubber&Plastic Products Co., Ltd.- Certification:CE, MET, CSA, UL, SA8000, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Popcorn, Chips

- Customized:Customized

Base Info

- Model NO.:KLD - Corn Snacks Plant

- Product:Puff Corn Cheese Ball Chips

- Craft:Extrusion

- Raw Materials:Rice, Wheat, Corn Starch, Potato Starch, etc.

- Products Shapes:Various Upon Your Specific Requirements.

- Motor:Siemens, ABB or Chinese Brand

- Electric Elements:Siemens, ABB or Chinese Brand

- Energy:Electricity, Oil Diesel, Gas, Steam

- Voltage:380V, 50Hz, 3phases (Adjustable)

- Main Screw:Twin Screw Extruder

- Condition:New

- Transport Package:Inside Plastic Bag, Outside Wooden Case.

- Specification:CE, ISO

- Trademark:Jinan Kelid Machinery Co., Ltd.

- Origin:Jinan, Shandong, China

- HS Code:84388000

- Production Capacity:350 Sets Per Month.

Description

Basic Info.

Model NO. KLD - Corn Snacks Plant Product Puff Corn Cheese Ball Chips Craft Extrusion Raw Materials Rice, Wheat, Corn Starch, Potato Starch, etc. Products Shapes Various Upon Your Specific Requirements. Motor Siemens, ABB or Chinese Brand Electric Elements Siemens, ABB or Chinese Brand Energy Electricity, Oil Diesel, Gas, Steam Voltage 380V, 50Hz, 3phases (Adjustable) Main Screw Twin Screw Extruder Condition New Transport Package Inside Plastic Bag, Outside Wooden Case. Specification CE, ISO Trademark Jinan Kelid Machinery Co., Ltd. Origin Jinan, Shandong, China HS Code 84388000 Production Capacity 350 Sets Per Month.Product Description

CE Turnkey Grain Puffed Corn Snacks Food Making Manufacturing PlantIntroduction:

Puffed Snacks/ Core Filling Snacks Production Line is improved and developed based on advanced technology by Jinan Kelide Machinery Co., Ltd. The machine performance and products quality reach to the most advanced level in the world. This line has features of flexible collocation, extensive applied raw materials, various snack and easy operation. It is full automatic from mixing, extruding, shaping, cutting, drying to flavoring in one-pass operation. By changing the moulds and process technology, you can produce various shapes of puffing snacks such as rings, flowers, balls, strips, moons, stars etc. Also, you can produce core-filling snacks with the same line. All the puffed food taste crispy, easy to be digested. They meet with great favor home and abroad.

Sample:

Flow Chart:

Mixer - Screw Conveyor - Extruder - Air Conveyor - Multi-layer Dryer - Hoister - Flavor and Roller - Cooling Conveyor

Technical Parameter:

| Model | KLD65-III | KLD70 | KLD85 |

| Installed Power | 76kw | 95kw | 178kw |

| Power Consumption | 54kw | 66kw | 125kw |

| Production Capacity | 140 - 160 kg/h | 240 - 260 kg/h | 500 kg/h |

| Dimension | 17x2x2.5m | 22x2x2.5m | 26x2x3.5m |

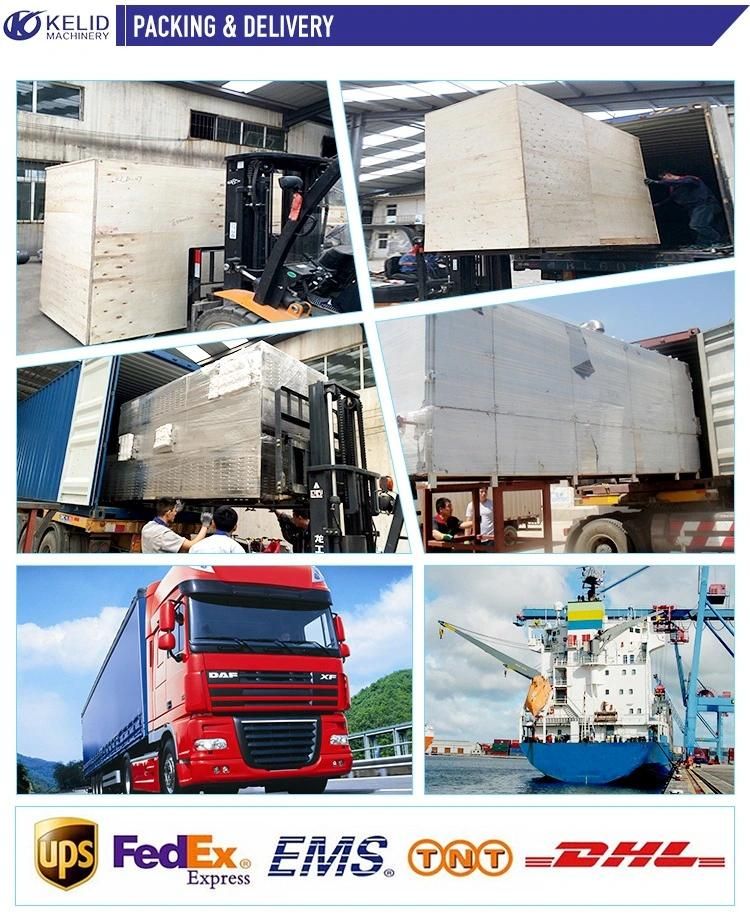

Packaging & Shipping:

Packing: Inside plastic bag, outside wooden case for Corn Snacks Plant(Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation: Shipping, train, express or upon clients' demands.

Professional Service:

1. Free Project planning and design services upon clients' special demands;

2. Overseas installation and training of equipment maintenance and operating personally;

3. Provide basic production techniques and formulas;

Our Company Information:

Contact Information:

If you have any needs or inquiries, please feel free to contact us.