200mm / 300mm / 400mm PVC Ceiling Wall Panel Extrusion Machine Production Line

Ningbo Easyget Co., Ltd.Base Info

Description

Auto stacker  Advantage of PVC ceiling and WPC wall panelNowadays, most of people do not just choose whitewashed walls when they dress up in the living room. Instead, they are more inclined to decorate with colorful and colorful wall panels. Extensive, it not only changes the past decoration style, but also does not need to worry about the wall dirt is not easy to remove, but many owners do not know much about wood-plastic WPC wall panels and PVC ceiling panels, the following editors will introduce the advantages of wood-plastic WPC wall panels and PVC ceiling panels.

Advantage of PVC ceiling and WPC wall panelNowadays, most of people do not just choose whitewashed walls when they dress up in the living room. Instead, they are more inclined to decorate with colorful and colorful wall panels. Extensive, it not only changes the past decoration style, but also does not need to worry about the wall dirt is not easy to remove, but many owners do not know much about wood-plastic WPC wall panels and PVC ceiling panels, the following editors will introduce the advantages of wood-plastic WPC wall panels and PVC ceiling panels.1.Waterproof, moisture-proof and insect-proofRelatively speaking, the service life of this kind of product will be longer than that of solid wood. Its biggest characteristics

2.Colorful and malleableThe color system of this kind of products is very rich, so there is a lot of room for users to choose from. At the same time, they can customize the required colors according to their preferences, which fully reflects the personalized style, especially some young people, who like this very much. Way of decoration.

2.Colorful and malleableThe color system of this kind of products is very rich, so there is a lot of room for users to choose from. At the same time, they can customize the required colors according to their preferences, which fully reflects the personalized style, especially some young people, who like this very much. Way of decoration. 3.High environmental protection and strong fire resistanceFrom the perspective of the materials currently used by the public, most of them pay more attention to the environmental

3.High environmental protection and strong fire resistanceFrom the perspective of the materials currently used by the public, most of them pay more attention to the environmental

performance of the products. The wood-plastic board does not contain benzene, and the formaldehyde content is 0.2, which is lower than the EO level standard. It is a European-level environmental protection standard. It saves the amount of wood used and is suitable for the national policy of sustainable development. In addition, it has strong fire resistance, self-extinguishes in case of fire, and does not produce any toxic gas.

Relate Products

Qingdao Tongsan Plastic Macxhinery CO.,LTD is professional for the Whole WPC production line with turnkey Project Service since 1997.We have all the WPC machines in factory stock and can be tested at anytime.

We have different type of WPC machines to make different WPC products from different raw material,

1, PVC WPC profile machine:

Material: 50%PVC+20% wood+20% caco3+ Chemical additives.

Product: WPC door frame, WPC wall panel, WPC decoration profiles indoor.

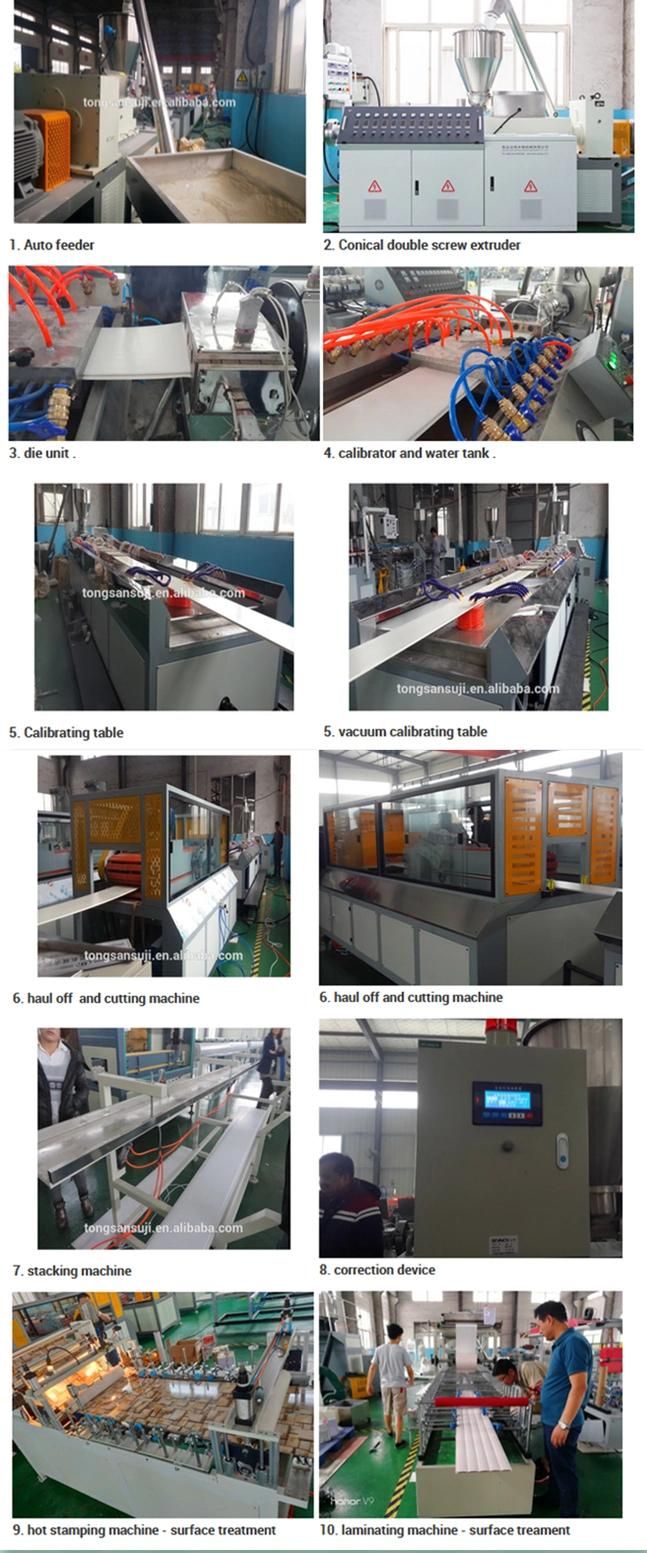

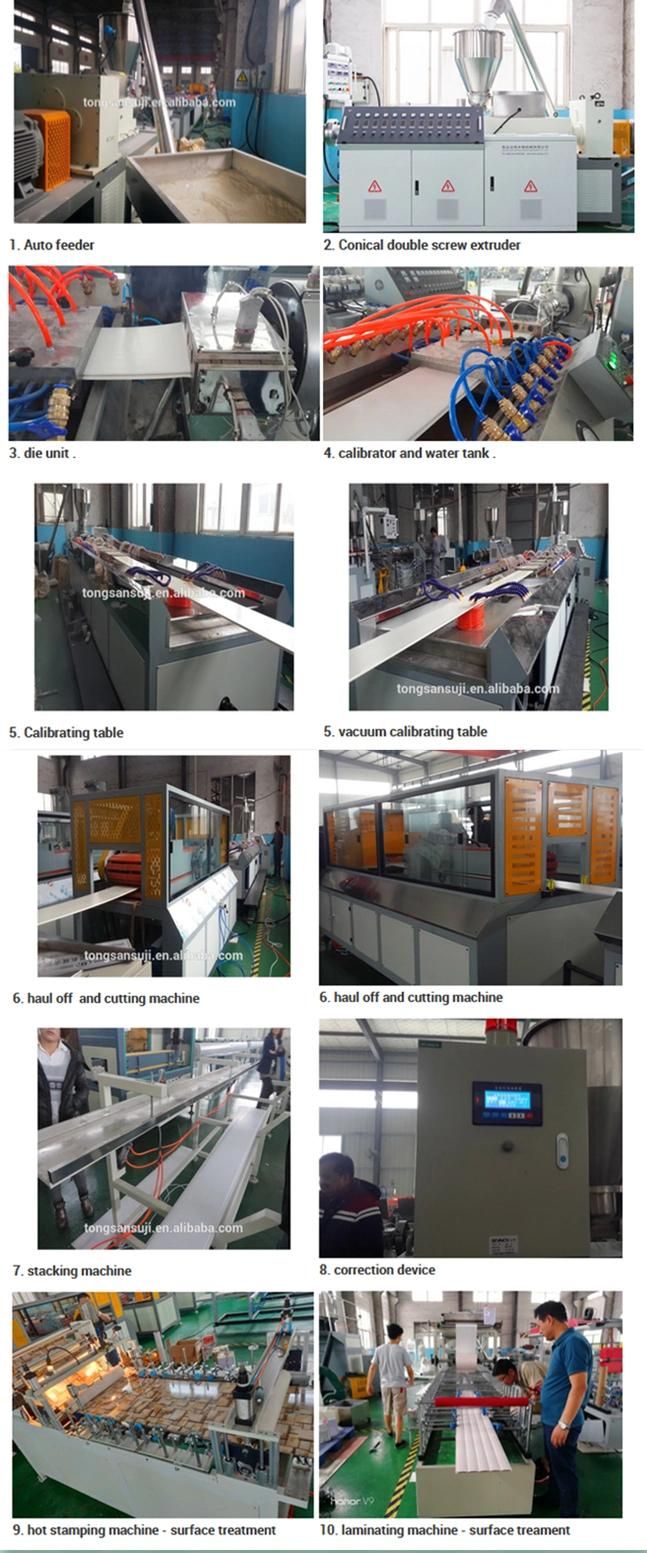

HGMSX series profile production line can continuously produce PVC/WPC profile,such as door and Window, wall panel, skirting etc.The production line consists of extruder, mould, calibrating platform, haul off and cutting machine and stacker.The extruder can produce PVC and WPC material profile by changing screw and mould.The calibrating platform adopts two-section structure and adopt double water tank, to ensure the stability of machine in production.The haul off and cutting machine is one body structure, the advantages of this unit are saving space and high precision cutting ,this unit also equip with dust collection system.The production line can optionally equip with PLC.

2, PVC WPC door machine:

Material:50% PVC+20% wood+20% caco3 +Chemical additives.

Product: Hollow Door panel, Cabinet Door, and other big profiles

HGMSM series door panel production line can continuously produce PVC/WPC door panel.The production line consists of extruder, mould, calibrating platform, Haul off machine, cutting machine and stacker.The extruder adopts specially designed screw, to ensure the door panel extrude steadily and foam uniformly.Calibrating platform adopts one body structure with adequate material.In case of shaking during production. Haul off machine adopts twin track structure ,the material of rubber block is silica gel.The haul off force is big and the speed is uniformly .Cutting machine adopts saw blade cutting, equipped with dust collection device.The production line runs stably and reliably during production.

3, PVC WPC board machine:

Material: 60% PVC+10% wood +20% CaCo3+ Chemical additives.

Product: Solid door panel, Furniture board, partition wall panel, decoration solid panel.

SJMSB series PVC/WPC foam board production line can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.The extruder adopts special screw. Calibrating platform equip width high efficiency cooling calibrator. Haul off machine adopts gear transmission to ensure uniform speed and high stabilize.The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

4, PP PE WPC granulating machiner

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

SHMS series granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

5,PP PE WPC profiles machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

Advantage of PVC ceiling and WPC wall panelNowadays, most of people do not just choose whitewashed walls when they dress up in the living room. Instead, they are more inclined to decorate with colorful and colorful wall panels. Extensive, it not only changes the past decoration style, but also does not need to worry about the wall dirt is not easy to remove, but many owners do not know much about wood-plastic WPC wall panels and PVC ceiling panels, the following editors will introduce the advantages of wood-plastic WPC wall panels and PVC ceiling panels.

Advantage of PVC ceiling and WPC wall panelNowadays, most of people do not just choose whitewashed walls when they dress up in the living room. Instead, they are more inclined to decorate with colorful and colorful wall panels. Extensive, it not only changes the past decoration style, but also does not need to worry about the wall dirt is not easy to remove, but many owners do not know much about wood-plastic WPC wall panels and PVC ceiling panels, the following editors will introduce the advantages of wood-plastic WPC wall panels and PVC ceiling panels.1.Waterproof, moisture-proof and insect-proofRelatively speaking, the service life of this kind of product will be longer than that of solid wood. Its biggest characteristics

are waterproof, moisture-proof, and insect-proof. Therefore, it effectively solves the problem of easy decay and expansion

deformation after absorbing water and moisture in humid and watery environments. The problem can be used in environments where traditional wood products cannot be applied.

2.Colorful and malleableThe color system of this kind of products is very rich, so there is a lot of room for users to choose from. At the same time, they can customize the required colors according to their preferences, which fully reflects the personalized style, especially some young people, who like this very much. Way of decoration.

2.Colorful and malleableThe color system of this kind of products is very rich, so there is a lot of room for users to choose from. At the same time, they can customize the required colors according to their preferences, which fully reflects the personalized style, especially some young people, who like this very much. Way of decoration. 3.High environmental protection and strong fire resistanceFrom the perspective of the materials currently used by the public, most of them pay more attention to the environmental

3.High environmental protection and strong fire resistanceFrom the perspective of the materials currently used by the public, most of them pay more attention to the environmentalperformance of the products. The wood-plastic board does not contain benzene, and the formaldehyde content is 0.2, which is lower than the EO level standard. It is a European-level environmental protection standard. It saves the amount of wood used and is suitable for the national policy of sustainable development. In addition, it has strong fire resistance, self-extinguishes in case of fire, and does not produce any toxic gas.

4.Simple installation and good sound absorptionFor the installation of this type of product, it does not need to be too complicated, which effectively saves operating time and costs. At the same time, it has good workability. For example, ordering, planing, sawing, drilling, etc. can be easily realized. In addition, its sound absorption The effect is good, the energy saving performance is good, and the indoor energy saving is as high as 30% or more.

Relate Products

Qingdao Tongsan Plastic Macxhinery CO.,LTD is professional for the Whole WPC production line with turnkey Project Service since 1997.We have all the WPC machines in factory stock and can be tested at anytime.

We have different type of WPC machines to make different WPC products from different raw material,

1, PVC WPC profile machine:

Material: 50%PVC+20% wood+20% caco3+ Chemical additives.

Product: WPC door frame, WPC wall panel, WPC decoration profiles indoor.

HGMSX series profile production line can continuously produce PVC/WPC profile,such as door and Window, wall panel, skirting etc.The production line consists of extruder, mould, calibrating platform, haul off and cutting machine and stacker.The extruder can produce PVC and WPC material profile by changing screw and mould.The calibrating platform adopts two-section structure and adopt double water tank, to ensure the stability of machine in production.The haul off and cutting machine is one body structure, the advantages of this unit are saving space and high precision cutting ,this unit also equip with dust collection system.The production line can optionally equip with PLC.

| Model | Profile Width | Extruder model | Motor power | Max.extrusion capacity | Calibrating platform length |

| HGMSC-200 | 200mm | 51/105 | 22kw | 100-120kg/h | 4000mm |

| HGMSC-300 | 300mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSC-400 | 400mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSCD-300 | 600mm | 65/132 | 37kw | 150-180kg/h | 8000mm |

| HGMSC-600 | 600mm | 65/13 or 80/156 | 37 or 75kw | 150-350kg/h | 6000mm |

2, PVC WPC door machine:

Material:50% PVC+20% wood+20% caco3 +Chemical additives.

Product: Hollow Door panel, Cabinet Door, and other big profiles

HGMSM series door panel production line can continuously produce PVC/WPC door panel.The production line consists of extruder, mould, calibrating platform, Haul off machine, cutting machine and stacker.The extruder adopts specially designed screw, to ensure the door panel extrude steadily and foam uniformly.Calibrating platform adopts one body structure with adequate material.In case of shaking during production. Haul off machine adopts twin track structure ,the material of rubber block is silica gel.The haul off force is big and the speed is uniformly .Cutting machine adopts saw blade cutting, equipped with dust collection device.The production line runs stably and reliably during production.

| Model | Door panel width | Door panel thickness | Extruder model | Motor power | Max extrusion capacity | Calibrating mould section |

| HGMSM-800 | 800 | 20-50mm | SJMS 80/156 | 75kw | 350-380kg/h | 2 |

| HGMSM-1000 | 1000 | 20-50mm | SJMS 92/188 | 110kw | 450-500kg/h | 3 |

| HGMSM-1200 | 1200 | 20-50mm | SJMS 92/188 | 110kw | 450-500kg/h | 3 |

3, PVC WPC board machine:

Material: 60% PVC+10% wood +20% CaCo3+ Chemical additives.

Product: Solid door panel, Furniture board, partition wall panel, decoration solid panel.

SJMSB series PVC/WPC foam board production line can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.The extruder adopts special screw. Calibrating platform equip width high efficiency cooling calibrator. Haul off machine adopts gear transmission to ensure uniform speed and high stabilize.The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

| Model | SJMSB-80/156 | SJMSB-80/173 | SJMSB-92/188 |

| Board thickness | 5-18mm | 3-30mm | 20-40mm |

| Board width | 1220mm | 1220mm | 1220mm |

| Max extrusion capacity | 350-380kg/h | 420-450kg/h | 500-550kg/h |

| Motor power | 75kw | 90kw | 110kw |

4, PP PE WPC granulating machiner

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

SHMS series granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

| Model | L/D ratio | Max.capacity | Motor power | Suitable material | Max.rotating speed | Wood powder percentage |

| SHMS-65 | 40:1 | 200-220kg/h | 75kw | Pe+wood powder | 500r/min | ≤75% |

| SHMS-75 | 40:1 | 300-350kg/h | 90kw | Pe+wood powder | 500r/min | ≤75% |

| SHMS-90 | 40:1 | 500-600kg/h | 132kw | Pe+wood powder | 500r/min | ≤75% |

5,PP PE WPC profiles machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

| Model | HGMSE-65 | HGMSE-80 |

| Extruder model | SJMS65/132 | SJMS 80/156 |

| Motor power | 37kw | 75kw |

| Mac.Extrusion capacity | 140-160kg/h | 220-250kg/h |

| Co-extruder(Optional) | SJ35/28 | SJ45/28 |