Core Filling Snack Production Line Project

Shenzhen Xinhui Plastic Products Co., Ltd.- Type:Grease Complete Sets of Equipment

- Application:All

- Appearance:Vertical

- Condition:New

- Customized:Customized

- Transport Package:Wooden Box

Base Info

- Model NO.:Core Filling Snack Production Line

- Trademark:COYO

- Origin:China

- Production Capacity:50000PCS,Year

Description

Model

Capacity

Power (KW)

Required Area

Operators

CFS100

100kg/h

65-80

250Square meters

2persons

CFS200

200kg/h

80-100

500Square meters

2persons

CFS300

300kg/h

120-150

650Square meters

2persons

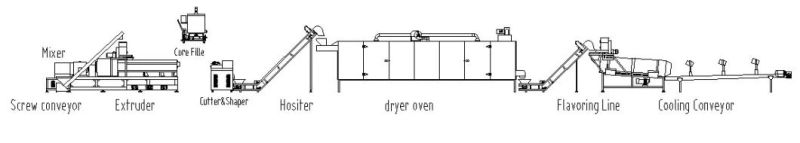

Processing Flow Chart

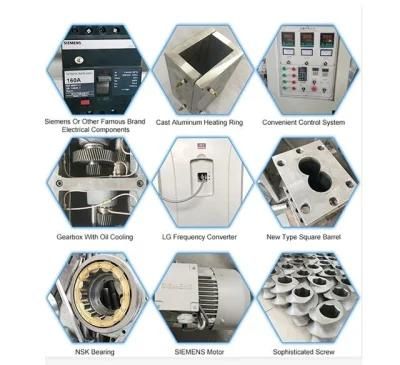

Main Machine Introduction

Mixer

1. The gear motor directly connected with the mixing wing is used to drive the mixing blade to stir efficiently.

2. Transmission efficiency 100%, increase torque. High efficient.

3. Equipped with high-precision gear motor to avoid motor burn out and prolong the service life of motor

Extruder

1. Feeding, driving device and rotary cutting device adopt frequency converter to adjust speed, with large driving force, stable operation and low energy consumption.

2. The screw is made of alloy steel and has a long service life. Segmented assembly screws are suitable for more materials and products.

3. Twin screw extruder can clean automatically.

4. Special designed gearbox, long service life

Core Filling Machine

Core filling machine plays an important role in leisure food production line. The machine is used to provide all kinds of jam for snack food center. The stuffing can be chocolate, cheese and cream. It can be mixed with egg yolk, milk powder, etc., and then put the core material evenly into the inflatable food.

Before the stuffing is extruded from the extruder by the core filler, we can feed the stuffing into the extruded food. The production line uses advanced extrusion technology to produce many popular leisure food on the market by changing the mold and production technology.

Cutting & Molding Machine

The multi-functional cutting molding machine is the main part of leisure food processing line, which can cut a variety of food shapes.

Dryer Own

1.With infrared heating tube heating, the temperature can be increased and decreased rapidly, the thermal inertia is small and the thermal efficiency is high.

2.Mesh belt transmission speed adjustable, with accurate temperature control device.

3.The bottom of the sliding plate of the dryer is easy to clean.

4.Suitable for dry non fried extruded snacks, nutritional powder, bread crumbs, pet food, textured vegetarian protein, etc

5.The hot air circulation device makes the heat energy in the dryer equal

6.Double roller chain and chain drive make the running stable

Spraying & Seasoning Machine

1. The equipment can be used in various puffed snacks and fried snacks.

2. The material will enter the drum automatically through the elevator

3. There is a seasoning quantity control device on the roller to ensure that the flavor is evenly distributed on the snacks

4. The roller is fully formed and there is no dead angle inside

5, the fuel injector can adjust the oil volume and spray evenly.

Packing Delivery

First, the brown rice is fed to rice polisher through screw head. the surface of the rice grain is polished by friction under a certain pressure and temperature. Through the polishing treatment, not only the floating surface of the rice grain can be cleared, but also the starch is pregelatinized and gelatinized on the surface of the rice starch, and the starch gelatinization makes up for cracks, thereby obtaining the smooth appearance, improving the storage life of the rice, therefore polished rice is very necessary.

Our Service

[Consulting Service] Our consultant provides you with pre-sales expertise consulting services, system evaluation, providing the best engineering solution

[Engineering Service] Set up special project team of technical, installation and sales for you. to design, install and commissioning a complete set of equipments, whole process tracking service.

[Training Service] Our experts in technology and management provide you long term production, operation, management, maintenance and other professional skills training, to help you train operation, technology, management personnel.

[Spare Part Service] We provides high-quality and reliable original accessories. And the service centers also keep store of a certain number of common accessories to meet the demand of rapid supply.

[Site service] Our service engineer goes deep into your site to solve practical problems. Conduct on-site training on the use of products and seek for improvement of a new way of thinking and method to reduce cost and increase efficiency.

FAQ

1. What is the delivery time of this machine if we book order right now?

We will deliver your order within 30-60days depend on different of machines.

2. How do you pack this machine for exporting?

We will provide packing which is suitable for the agreed means of transportation and for the foreseeable conditions of storage at the destination.

3. How can we make inspection before delivery?

We welcome you send your inspection manager come to our factory for inspection or you can nominate international the third part inspection company.

4. What is the warranty for your machine?

If any defect or non-conformity arising from faulty design, materials, we shall eliminate defects or replace machine.

5. What is the installation requirement of this machine?

The foundation of the machine should be with sufficient strength to support the weight of the machine.

There should be enough space around the machine for maintenance and inspection.