600mm PVC Furniture Edge Band Banding Sheet Production Line Making Machine

CHINA GTL TOOLS LIMITEDBase Info

Description

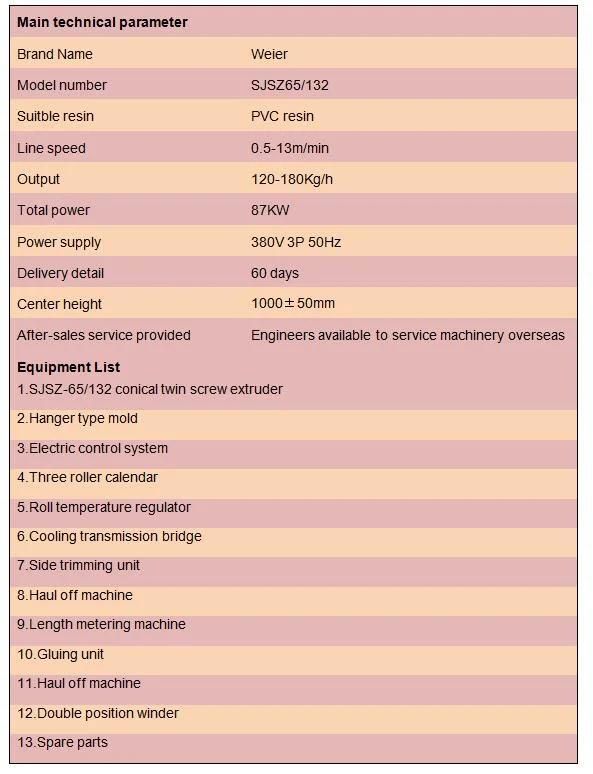

Basic Info.

Model NO. SJSZ80/156 Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Total Power 87kw Output 120-180kg/H Splitting Machine Automatic Scrfp Edge Self-Motion Adjustable Transport Package Nude Packing Specification 22*2.5*3 Trademark weier Origin Shandong HS Code 84772090 Production Capacity 20set Per MonthProduct Description

PVC Edge banding sheet production line---Produce Application---Plastic resin are fed into the barrel of the extruder and conveyed by the screw,the heaters which are outside of the barrel of the extruder as well as the friction from the rotation of the screw melt the plastic pellets into a sheet mold and then placed on a three-roll calender,the produced sheet goes through the bottom and middle roll,wrapping around back of the middle roll and then back to the top roll or other methods as shown in sheet calender picture,these rolls are helpful to take the heat out of the sheet,after the sheet comes off the roll,it moves down the conveyor to the end of sheet line where the edge trimmer cuts the sheet to width as well as a sheet shear cutter to length.

Process of pvc sheet (400mm, 600mm) edge banding whole production line:

1. pvc sheet edge banding extrusion line ( twin screw extruder---T type die---three roller calender--cooling bracket--haul off-winder,etc)

2. slitting machine

3. three color printing machine or hot stamping machine for choice

Write to me,you'll get more information about the line.The price,the detail parammeters,the arrangement plan for the line and so on!

---Packing & Delivery---

---Exhibition Certificate & Shipping---

---Contact us---