Commercial Bread Bakery Conveyor Belts Freezing Room Equipment

Chongren Longtime International Co.- Usage:Biscuit, Cake, Pizza, Bread

- Power Source:Electric

- Timing Device:With Timing Device

- Type:Spiral Conveyor

- Voltage:380V

- Customized:Customized

Base Info

- Model NO.:ACN-20200619002

- Function:Bread Cooler,Food Cooler,Cooling Tower

- Conveyor Belt Width:Customize

- Tower Diameter:Customize

- Input and Output Direction:Customize

- Cooling Time and Capacity:Customize

- Pre Cooling Room Temp:-5 to 50 Celsius

- Transport Package:Wooden Case Packing

- Specification:CE

- Trademark:AOCNO

- Origin:Hebei, China(Mainland)

- HS Code:843880000

- Production Capacity:15 Sets,Year

Description

Basic Info.

Model NO. ACN-20200619002 Function Bread Cooler/Food Cooler/Cooling Tower Conveyor Belt Width Customize Tower Diameter Customize Input and Output Direction Customize Cooling Time and Capacity Customize Pre Cooling Room Temp -5 to 50 Celsius Transport Package Wooden Case Packing Specification CE Trademark AOCNO Origin Hebei, China(Mainland) HS Code 843880000 Production Capacity 15 Sets/YearProduct Description

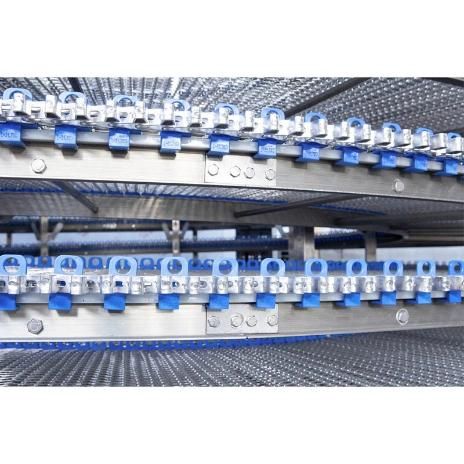

commercial bread bakery conveyor belts freezing room equipment1.Spiral cooling tower conveyor

Suitable for cooling all kinds of baking foods and fried foods.there are two types: Natrual cooling & Controlled Freezing

Working Principle:

The Main Spindle drives per gear in each layer, and gears drives per mesh belt in each layer, so that the power of gear motor to be transmitted. Each gear has smart power transmission device to adjust the transmission power automatically.

Characteristics of Spiral Cooling/Freezing Tower(transmit layer by layer):

1. Nylon card rail in both sides are stable, without machine jams or upturning fault.

2. Due to its intelligent transmission technology, the mesh belt in each layer can adjust its tension automatically, keep the transmission force in each layer equal.

3. Adopts high strength Nylon card rail and low friction PP guide rail, resulting in lubricant in rotating unnecessary, scraps caused by friction not to drop or pollute food.

4. Food input and output directions to be customized according to customer's workshop layout, such as Input in Lower entrance, well come out from higher exit, Input in Higher entrance, well Output from Lower exit, Twin Inputs+Twin Outputs, Three Inputs+Three Outputs, Round Circle or Ellipse Spiral Towers

| Material | The mesh belt is made of 304 stainless steel and the skeleton is made of 304 and 201 stainless steel square tubes. |

| Belt width rang | 200 mm-1300 mm |

| Belt length range | Single tower length 50 meters - 1200 meters |

| Tower diameter rang | 1.5-12 Meters |

| Layer heigh | Spiral tower up to 6 meters |

| Tower Layer range | 1-40 layers |

| Entrance&exit direction | Low inlet high exit high inlet low exit two in and two out, three in and three out, ellipse |

2.Spiral Proofer room

It can be used as spiral proofer, assembly with production line, which improves the production efficiency greatly, users can monitor all proof process via computer control system. Optional Device: Steam System and Heating System. The Spiral Cooling/Freezing Tower is suitable for bulk and packaged foods. It runs as usual at a temperature of 40 ºC below.

| Humidity Control | 60%-90% |

| Proofing time adjustable(min) | 30min-120min |

| Belt width range(mm) | 230mm-1100mm |

| Heating temperature | 30ºC-45ºC |

| Humidification way | Ultrasonic Humidifier |

3.Fast freezing

* Deep-Freezing Spiral Tower designed according to usage of foods.

* Cooling/Freezing Settlement customize for bread,pizza,dumplings,wonton,fresh vegetable,fish or other meat.

Fast freezing room temperature:-45ºC-5ºC

Pre cooling room temperature: -5ºC-30ºC

We can customize according to your capacity.